I like Board & Batten, it's a classical old style and I highly encourage it!

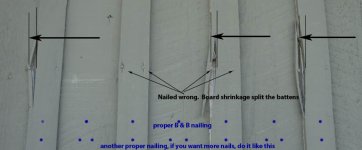

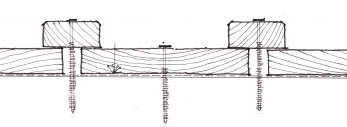

It's not used much anymore because people don't understand the nailing pattern necessary. There is a specific way it needs to be nailed, or your boards will split. Basically it's one vertical row of nails in the middle of each board, and in the middle of each batten. You have to let the wood on the left and right of each nail shrink (or expand) with each season. They must "float".

You CANNOT nail board& batten to 1/2" sheathing, sheathing does not offer even 25% if the engagement you nee to hold a board& batten nail. You have to use LONG nails, they need a couple inches of engagement or the boards will cup and pull the nails out. You need horizontal "Gurts" to nail to. You CANNOT nail wherever you feel like it, or wherever the board is cupping, because when the board shrinks, if it can't float it will split. Also consider that the battens nails have to "gap' the thickness of the boards, they are extra long. Batten nails do NOT go thru the boards, they go thru the gap between the boards. Be sure to do your research on this special classical siding technique, there's lots of info in books and on the web.

You have to really UNDERSTAND what's happening, and why the B&B method was developed. As Ron said it was developed because people had to saw up trees and nail them on the house, they had no time or place to wait for the boards to dry.

Some people use T1-11 siding and nail battens on it, that looks "ok" but it's cheating. I hope you are doing the real thing! Don't use pine boards for outdoor siding, use fir or cedar, pine won't last but a few years exposed to weather.