LD1

Epic Contributor

Trying to plan out and decide how I want to build my bridge crane in the shop.

I cannot afford a new beam big enough for the 38' span. So will wait til the right one comes along on craigslist or whatever. There are some good ones on there now so I though I'd run some ideas by the board.

My main concern is with a 38' span, its gonna take a HEAVY beam, or a TALL beam, or a combination of both.

The HEAVY beams in the 16-18" range would be nice if I could find one. My concern with a taller beam is hanging a load from the bottom, and in order to move it you are pushing and pulling on the chain "twisting" the beam possibly causing the top to buckle.

I have colums, beams, and track for the main bridge to run on. It will have 12' of run, the a push-trolley on the 38' span. According to my math, minimum beams needed for a 10k max load SF are

5:1 SF....................3:1 SF

W12x106...............w12x72

W14x99.................w14x61

W16x89.................W16x57

W18x86.................W18x55

W21x83.................W21x50

W24x68.................W24x55

Ill probably never ever lift 10k, but my chain hoist is a 5t

Current craigslist beam offerings are:

W24x104 39' long. Overkill and more than I want to spend @ $1250 but would get the job done for sure if I can get it up there.

W12x72....2 of these 25' long each. Good price. $600 for both. Could be welded together, but under the 5:1 SF most cranes are designed for. Could take the extra 12' and weld to the top in the middle to gain some strength and bridge over the seam of splicing them together.

W24x84 38' long. Will easily handle the load and be easier to lift than the W24x104, but is about 3x weaker in the horizontal direction, and cost just as much. So for the price, I'd rather get the heavier beam and worry about setting it.

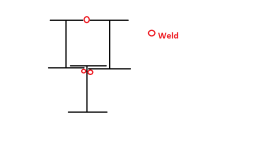

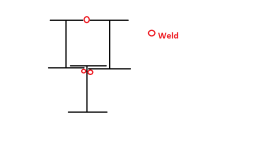

S12x35....30' long but he has 7 of them. I dont normally like S-type beams for long spans as they are too narrow and easier to twist or deflect in the horizontal direction with a single beam span and no flooring or nothing tying in multiple beams. But I have a crazy idea about attaching 3 of them together. Look at the picture for a cross-section:

Being two wide would solve the problem of S-type beams being weak in that direction. The bottom beam to gain depth would "probably" get the strength I need, but cannot find any formulas for stacking beams. The bottom beam would actually be about 1' shorter on each end, as the top two beams would extend and set on the "truck" that is riding on the rail.

My gut says this would be a sufficient setup, as overall depth would be 24" and plenty heavy. But the best part is this would cost me under $500 , and I could set them in place a beam at a time

Thoughts, Opinions, Am I crazy?

I cannot afford a new beam big enough for the 38' span. So will wait til the right one comes along on craigslist or whatever. There are some good ones on there now so I though I'd run some ideas by the board.

My main concern is with a 38' span, its gonna take a HEAVY beam, or a TALL beam, or a combination of both.

The HEAVY beams in the 16-18" range would be nice if I could find one. My concern with a taller beam is hanging a load from the bottom, and in order to move it you are pushing and pulling on the chain "twisting" the beam possibly causing the top to buckle.

I have colums, beams, and track for the main bridge to run on. It will have 12' of run, the a push-trolley on the 38' span. According to my math, minimum beams needed for a 10k max load SF are

5:1 SF....................3:1 SF

W12x106...............w12x72

W14x99.................w14x61

W16x89.................W16x57

W18x86.................W18x55

W21x83.................W21x50

W24x68.................W24x55

Ill probably never ever lift 10k, but my chain hoist is a 5t

Current craigslist beam offerings are:

W24x104 39' long. Overkill and more than I want to spend @ $1250 but would get the job done for sure if I can get it up there.

W12x72....2 of these 25' long each. Good price. $600 for both. Could be welded together, but under the 5:1 SF most cranes are designed for. Could take the extra 12' and weld to the top in the middle to gain some strength and bridge over the seam of splicing them together.

W24x84 38' long. Will easily handle the load and be easier to lift than the W24x104, but is about 3x weaker in the horizontal direction, and cost just as much. So for the price, I'd rather get the heavier beam and worry about setting it.

S12x35....30' long but he has 7 of them. I dont normally like S-type beams for long spans as they are too narrow and easier to twist or deflect in the horizontal direction with a single beam span and no flooring or nothing tying in multiple beams. But I have a crazy idea about attaching 3 of them together. Look at the picture for a cross-section:

Being two wide would solve the problem of S-type beams being weak in that direction. The bottom beam to gain depth would "probably" get the strength I need, but cannot find any formulas for stacking beams. The bottom beam would actually be about 1' shorter on each end, as the top two beams would extend and set on the "truck" that is riding on the rail.

My gut says this would be a sufficient setup, as overall depth would be 24" and plenty heavy. But the best part is this would cost me under $500 , and I could set them in place a beam at a time

Thoughts, Opinions, Am I crazy?