as far as expanded metal Im really thinking more like a grate. I don't know what its called really. Its expanded metal where the diamond shapes are actually verticle with little grooves on them. The are very study I've seen them used on cat walks and overhead suspended decks in warehouses. I thought King it had but but I didn't see it online.

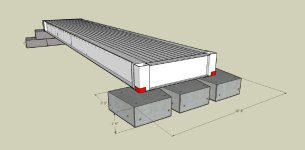

Next is the I-beam or truss. this 20footer is 221.00

I'm not sure about the strength or anything though.

Then there is the abutment. I'm sure I can pour a couple of those. There is also this option, quickblocks. Supposedly you can buy these comparible to concrete. I don't know yet.

the trailor option isn't a bad idea. I just wonder about handling once you got it there.

Next is the I-beam or truss. this 20footer is 221.00

I'm not sure about the strength or anything though.

Then there is the abutment. I'm sure I can pour a couple of those. There is also this option, quickblocks. Supposedly you can buy these comparible to concrete. I don't know yet.

the trailor option isn't a bad idea. I just wonder about handling once you got it there.