The

L48 again has reverse !! All that noise inside the regulator was due to the "neutral" adjustment being off.

I had earlier found the regulator valve didn't move freely but after freeing it up and reinstalling it the behavior was still the same. So then I tested the regulator on the bench with air instead of oil from the charge pump - with the valve "centered" the two outlet ports (pic above) should have been blocked. But the forward port was getting air in neutral. That would mean that moving toward reverse both sides of the piston were getting pressure and it didn't move. Anyway I adjusted the stop to put the valve in the middle of the sweet spot (no flow in neutral). With the regulator back on the tractor, the HST pedal put it in reverse right away.

The thing I noticed is how narrow the regulator's sweet spot is. Pretty tricky to get it just right so both ports are blocked in the center. This is good in a way because when it's right it makes a very responsive linkage. But it also turned on another light bulb.

The picture below is looking up from under the tractor. The bottom of the regulator sticks down and gets rubbed by grass and weeds, sticks etc. - notice the gray paint is worn thru to the white primer. When I first took the regulator off I noticed the end of the adjusting screw was slightly damaged (deformed enough that an Allen wrench wouldn't go in) I used a die grinder on the bad spot and didn't think about it much. But the bottom of the regulator housing is aluminum and anything that could whack the steel adjusting screw hard enough to deform it might cause just enough permanent deformation of the aluminum to upset the regulator's sweet spot. We're talking half a millimeter or less, so it's plausible. Couldn't tell for sure whether the locknut had been loosened or if it had ever been adjusted before. But regardless it works now.

Part cost: 1 regulator gasket $10

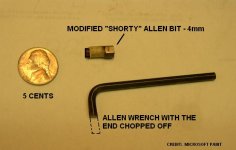

Tool cost: 1- T25 torx bit (cut short) $7

Materials: about 1 qt SUDT not recovered - $10

Labor cost: would have watched the Mekum Muscle Car Auction anyway

Not paying Kubota's confiscatory HST part prices: quietly satisfying

Dick B