3RRL

Super Member

- Joined

- Oct 20, 2005

- Messages

- 6,931

- Tractor

- 55HP 4WD KAMA 554 and 4 x 4 Jinma 284

Chris, these are from last Summer when I was fixing up my Howse medium duty brush hog.

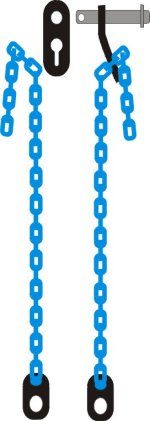

I made some leveling gauge wheels that fit the brush hog and other implements such as my box blade and rake. They are hydraulic controlled so I can raise the rear or front while mowing. I don't have a level spot where I mow so I use the position control and 3 pt for raising or lowering the front and the hydraulic wheels for the rear. I have solid swaybars that are adjustable by pins and a slot for some movement.

Rob-

I made some leveling gauge wheels that fit the brush hog and other implements such as my box blade and rake. They are hydraulic controlled so I can raise the rear or front while mowing. I don't have a level spot where I mow so I use the position control and 3 pt for raising or lowering the front and the hydraulic wheels for the rear. I have solid swaybars that are adjustable by pins and a slot for some movement.

Rob-