Billybob69

New member

So need to post a couple of links so this is post #2

I swear I will get to the real issue on post #4

I swear I will get to the real issue on post #4

Mybe the endcap s screws is loose ?And engine on

Mybe the endcap s screws is loose ?

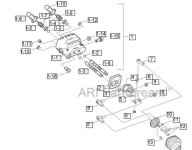

On the other side of where the lever goes inI maintain all vehicles at my place but have never gotten into the breakdown of hydraulic valves. Is there a diagram somewhere showing parts and layout etc? Or can you clarify "end cap"? More than able to do the job just don't like going in blind.

Thanks!

You need to remove the spool cap on the far side of the valve body from the joystick. The float spool controller will be the longer of the 2 spool caps. In the cap, there will be 3 ball bearings that engage is a slot in a spool washer. If the washer gets warn, the bearings won't lock in the groove. Often, you can spin the washer so the bearings have a fresh lip to lock in and re-assemble the spool cap. Make sure you grease the bearings and spring well before assembly. The grease will keep the 3 bearings in the holes at the end of the spool controller.

Hope this helps,

I felt the need to exit right quickly from my DS3510 one day, and broke the aluminum bracket on the joystick assembly. Had to manually activate the valves to get the bucket up and get the tractor out of the hole it was in. Instead of buying a new valve assembly (individual part not sold by itself) I fabbed a replacement - but had no float detent. I used it for a year that way, until I wanted a grapple. I bought a huge joystick valve assembly from Surplus Center (sponsor here at TBN) with a third function built in.

In the process of plumbing that bad boy, I was at a local hydraulic shop. I mentioned the detent issue to the counter guy, and he said that was an easy fix. Said they could do it for $40 - their minimum labor charge. I didn't pursue it, as I was replacing the unit anyway. If you have a hydraulic shop nearby, you could take it there.

Or replace the whole thing with a new unit. 2 Spool 12 GPM Joystick Loader Control Valve | Joystick Valves | Hydraulic Valves | Hydraulics | www.surpluscenter.com

Yes, the spool cap is similar to 1-6 in your picture. The longer cap is the float cap. Be careful not to loose the ball bearings when you remove the cap!!