Hey guys, help me out with an opinion. A while back I fabricated a 40 bucket for my loader. It replaced a 66 bucket which was too wide for my needs. I tried to copy the symmetry of the replaced bucket, but it did not work as I had hoped. My next planned move would be to position the bucket cylinder parallel to loader arm which it would give more curl-up travel with the bucket at ground level. How much curl-up at ground level I should have, I have no idea. Would 4 in be appropriate? This move would probably give more curl-down travel with the bucket in high position. Before I start fabricating and positioning new brackets, however, I could use an opinion.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bucket Symmetry Question

- Thread starter NCMau

- Start date

- Views: 8104

/ Bucket Symmetry Question

#1

BukitCase

Elite Member

- Joined

- Feb 17, 2012

- Messages

- 2,753

- Location

- Albany OR

- Tractor

- Case 580B, Long 460, Allis-Chalmers 160

You definitely need to do SOMETHING to increase the RANGE of curl - it doesn't curl UP enough at ground level enough to keep a load in the bucket, nor does it curl DOWN enough at high level to dump.

My 580B's loader is obviously a whole different animal (1 yd bucket just under 7 foot wide, reversed bell-crank linkage with trunnion mount cylinders, etc) but it works EXACTLY as I would want it to -

At ground level, curl has the bucket lip up off the ground by about 8" (probably about a 4/12 pitch) and full dump has BOTH the bottom and top edges touching the ground - at full height, full curl would dump part of a full bucket BACK onto the tractor (if it went any further,) and full DUMP has the bucket floor only about 30 degrees from VERTICAL.

About the only thing that wouldn't dump properly under those conditions would be if I filled the bucket with our crappy clay soil and let it sit thru a rain storm and dry out BEFORE trying to dump it

I've seen enough of your posts to know you're a pretty clever guy, and I've come up with a few pretty cool ideas myself, but CHANGING bucket geometry is NOT one of them - but if moving attach points so the cylinders are parallel to loader arms at full curl will actually INCREASE the RANGE, then that is what I'd try - I don't think doing that would hurt your leverage much, since your new bucket is so much smaller than the original.

Sorry I'm not more help, but hopefully I've at least given you somethin' to shoot for :confused3: ...Steve

My 580B's loader is obviously a whole different animal (1 yd bucket just under 7 foot wide, reversed bell-crank linkage with trunnion mount cylinders, etc) but it works EXACTLY as I would want it to -

At ground level, curl has the bucket lip up off the ground by about 8" (probably about a 4/12 pitch) and full dump has BOTH the bottom and top edges touching the ground - at full height, full curl would dump part of a full bucket BACK onto the tractor (if it went any further,) and full DUMP has the bucket floor only about 30 degrees from VERTICAL.

About the only thing that wouldn't dump properly under those conditions would be if I filled the bucket with our crappy clay soil and let it sit thru a rain storm and dry out BEFORE trying to dump it

I've seen enough of your posts to know you're a pretty clever guy, and I've come up with a few pretty cool ideas myself, but CHANGING bucket geometry is NOT one of them - but if moving attach points so the cylinders are parallel to loader arms at full curl will actually INCREASE the RANGE, then that is what I'd try - I don't think doing that would hurt your leverage much, since your new bucket is so much smaller than the original.

Sorry I'm not more help, but hopefully I've at least given you somethin' to shoot for :confused3: ...Steve

I would duplicate the current loader geometry in wood, then experiment with different locations until I got what I wanted. One inch Sch40 PVC inside 1 1/4 inch makes a good trial "cylinder" that will actually move. Or just use two pieces of wood, one extended length and the other retracted length.

Bruce

Bruce

Xfaxman

Super Star Member

- Joined

- Feb 8, 2013

- Messages

- 12,875

- Location

- Guthrie, OK

- Tractor

- Toolcat 5610 G - Bobcat V417 - TORO+Loader

The hole for the curl cylinder needs to come down closer to the lower pivot pin.

Leave a little clearance above the loader arms at full curl down or it will bend the rod.

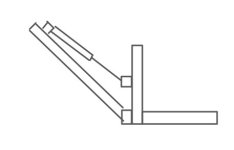

This is the way Kwik-Way built the bucket on mine:

This is the way I did the brush fork:

And the box blade:

Leave a little clearance above the loader arms at full curl down or it will bend the rod.

This is the way Kwik-Way built the bucket on mine:

This is the way I did the brush fork:

And the box blade:

Last edited:

sidecarist

Silver Member

Xfaxman is 100% correct here. you need to lower the top pin location. be careful not to get them too close, but that should do it for you.

Good Luck!

Good Luck!

You definitely need to do SOMETHING to increase the RANGE of curl - it doesn't curl UP enough at ground level enough to keep a load in the bucket, nor does it curl DOWN enough at high level to dump.

My 580B's loader is obviously a whole different animal (1 yd bucket just under 7 foot wide, reversed bell-crank linkage with trunnion mount cylinders, etc) but it works EXACTLY as I would want it to -

At ground level, curl has the bucket lip up off the ground by about 8" (probably about a 4/12 pitch) and full dump has BOTH the bottom and top edges touching the ground - at full height, full curl would dump part of a full bucket BACK onto the tractor (if it went any further,) and full DUMP has the bucket floor only about 30 degrees from VERTICAL.

About the only thing that wouldn't dump properly under those conditions would be if I filled the bucket with our crappy clay soil and let it sit thru a rain storm and dry out BEFORE trying to dump it

I've seen enough of your posts to know you're a pretty clever guy, and I've come up with a few pretty cool ideas myself, but CHANGING bucket geometry is NOT one of them - but if moving attach points so the cylinders are parallel to loader arms at full curl will actually INCREASE the RANGE, then that is what I'd try - I don't think doing that would hurt your leverage much, since your new bucket is so much smaller than the original.

Sorry I'm not more help, but hopefully I've at least given you somethin' to shoot for :confused3: ...Steve

Steve, you along with the others were great help.Hoping to get the 8 in up-curl at ground level, I will pursue the cylinder parallel mounting. This is the least painful approach, other than doing unthinkable mods. I would be happy even to get 4 in. Thanks for the help.

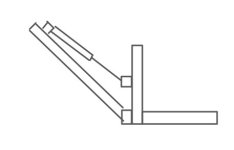

By modifying the existing brackets and pivot points , I was able to place the bucket cylinders almost parallel to the loader arms. That gave me 6 inches curl-up at ground level and a better dump angle at a full height. I am happy and thanks for the opinions.

Attachments

Xfaxman

Super Star Member

- Joined

- Feb 8, 2013

- Messages

- 12,875

- Location

- Guthrie, OK

- Tractor

- Toolcat 5610 G - Bobcat V417 - TORO+Loader

Good job. :thumbsup: