Daver1963

Platinum Member

- Joined

- May 14, 2013

- Messages

- 675

- Location

- Idlewild, Tn

- Tractor

- Kubota L2800DT w/LA524 FEL, Cub Cadet XT1

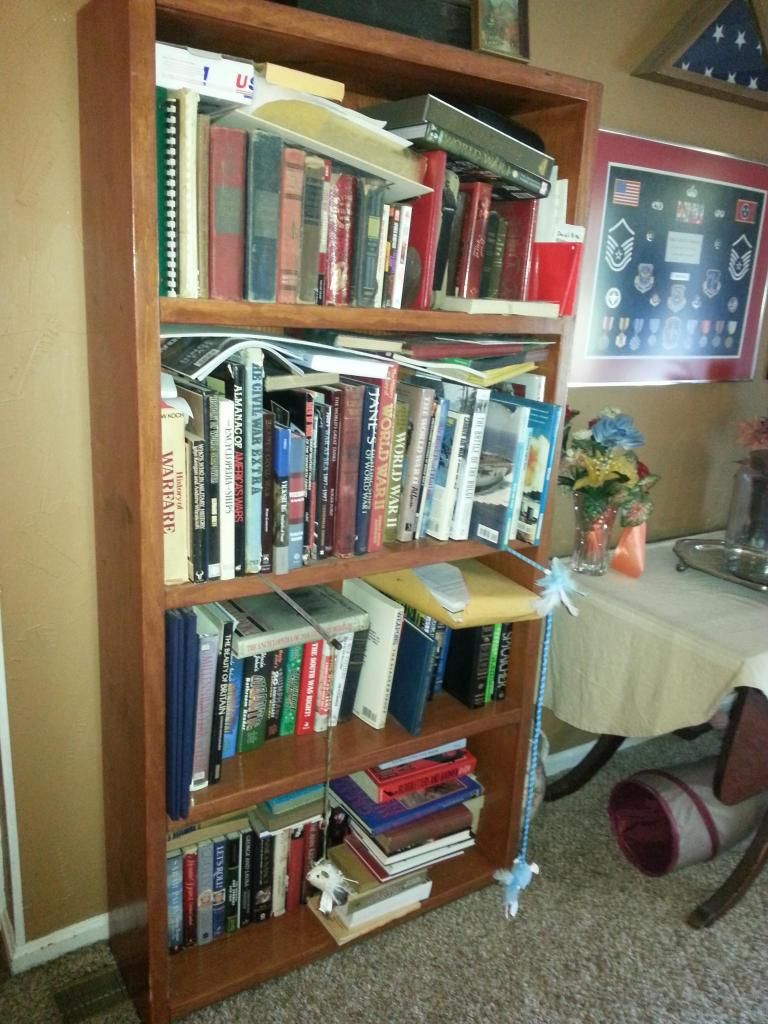

Here is a book shelf I built a few years ago. I may have overdone it, but I knew I would be putting heavy books on it. It is made from 2"X12" pine all around with 1/4" plywood backing. I used three inch decking screws and predrilled the holes. I also countersunk the screws about 1/2 inch and then used a quarter inch dowel to make plugs so that no screws would show. After that was two coats of cherry stain and a coat of clear poly.