Green Acres Homestead

Veteran Member

- Joined

- Dec 11, 2010

- Messages

- 1,174

- Tractor

- Kubota L4740 sold. As of Jan 2023 I have a new L2502.

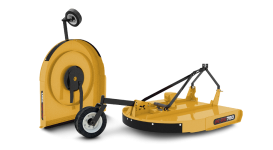

New to bush cutting. Bought a new mk martin bushhog. Works great but as I went forward to reverse I watch the wheel swivel and I thought that the crazy wheel frame is going to bend. I tried picking up the bushhog when changing direction but I forgot sometimes. It bent. I’m pounding it back straight.

Anyway I’m thinking of reinforcing it so it doesn’t bend but I’m thinking I may weld something so the wheel does swilvel 360 degrees. When I’m backing up I’ll just keep the wheel off the ground. Do you think this will work? When you change direction do you let the grass eventually swivel the wheel then drop it to the ground or do you just let the wheel stay on the ground and let the wheel swivel happen at full weight and pressure?

Anyway I’m thinking of reinforcing it so it doesn’t bend but I’m thinking I may weld something so the wheel does swilvel 360 degrees. When I’m backing up I’ll just keep the wheel off the ground. Do you think this will work? When you change direction do you let the grass eventually swivel the wheel then drop it to the ground or do you just let the wheel stay on the ground and let the wheel swivel happen at full weight and pressure?