Scooby074

Super Member

Just a couple easy little mods here to take care of some annoyances with the factory BX top link

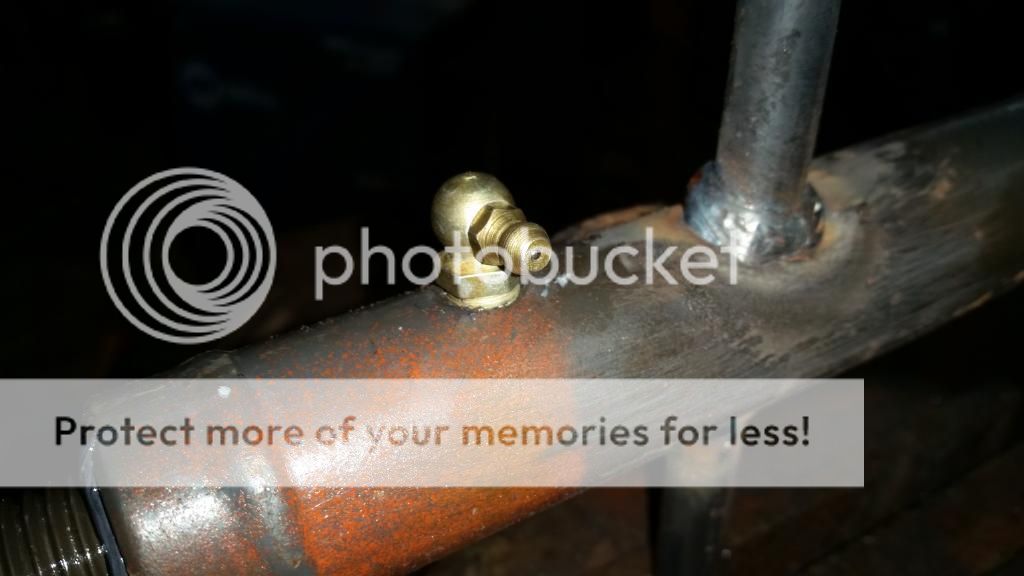

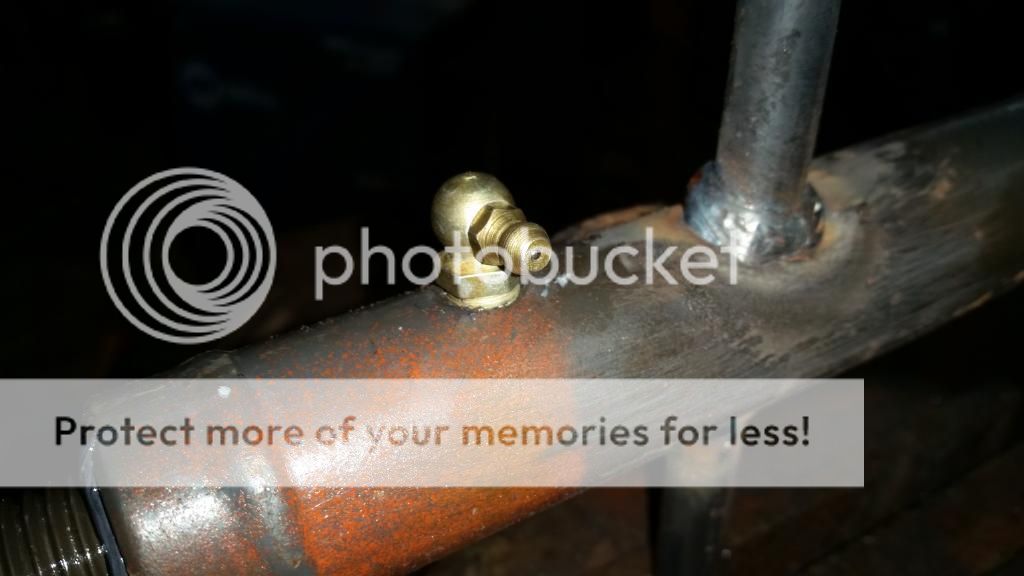

First is to add a couple grease fittings. Under the black caps, there is a hole that is used to push in a roll pin when the link was built. This hole is just about the right size for a 1/8NPT grease fitting. I tapped the hole with a 1/8 NPT tap, no drilling required. There is a fair bit of clearance between the tube and the adjusting screw inside, the threads only go about 1" up the top link tube.

Now I can squirt a shot of grease in there once and a while to keep things smooth.

Second was to add some handles to the link to allow for easier adjustment, the welded on chain link is basically useless. The handles are 5" long, 1/2" round.

Lubed with some Cat 5% moly

Installed with a fresh coat of Kubota gray

First is to add a couple grease fittings. Under the black caps, there is a hole that is used to push in a roll pin when the link was built. This hole is just about the right size for a 1/8NPT grease fitting. I tapped the hole with a 1/8 NPT tap, no drilling required. There is a fair bit of clearance between the tube and the adjusting screw inside, the threads only go about 1" up the top link tube.

Now I can squirt a shot of grease in there once and a while to keep things smooth.

Second was to add some handles to the link to allow for easier adjustment, the welded on chain link is basically useless. The handles are 5" long, 1/2" round.

Lubed with some Cat 5% moly

Installed with a fresh coat of Kubota gray