4570Man

Super Star Member

- Joined

- Apr 7, 2015

- Messages

- 18,498

- Location

- Crossville, TN

- Tractor

- Kubota M59, Kubota L3800, Grasshopper 428D, Topkick dump truck, 3500 dump truck, 10 ton trailer, more lighter trailers.

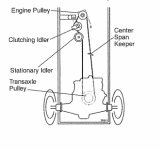

Maybe cheaper, but growing up the Cub Cadet mower had a much superior and smoother transition use a pulley system then any electric clutch that slams in that I’ve seen since.

You could control how fast mower comes up to speed and how much engine rpms dip at the same time.

That Cub got replaced by a Honda that also used a pulley system that slams in as hard as an electric clutch.

It really depends on the set up and linkage.

I agree. It’s cheap in price but there’s nothing second rate about the way it works. My grandpas G4200 Kubota used that method and it’s all worked smooth and hasn’t caused any problems.