This is the second time this plate assembly cracked in the last week. I’m using a hydraulic top link and apparently that’s what’s causing this plate to crack, I just don’t know how. Anyone have any ideas why it’s breaking this piece? The top link does not come into contact with this piece in anyway. I’m pretty confused.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Can’t run a hydraulic top link on a Case 75c?

/ Can’t run a hydraulic top link on a Case 75c?

#1

rScotty

Super Member

- Joined

- Apr 21, 2001

- Messages

- 9,448

- Location

- Rural mountains - Colorado

- Tractor

- Kubota M59, JD530, JD310SG. Restoring Yanmar YM165D

It is hard for me to tell from those pictures, but it may be that you are trying to run a hydraulic top link on a tractor that has automatic draft control engaged. Those two systems can work against each other with tremendous power. If that's the case, I'm not surprised it will break things like shown.

Be sure to turn off the automatic draft control and lock the top link attachment point before using a hydraulic top link.

Be sure to turn off the automatic draft control and lock the top link attachment point before using a hydraulic top link.

I’ve got no idea how to engage or disengage that. I’ve gone through the manual a few times and can’t find anything. Any chance you could help?It is hard for me to tell from those pictures, but it may be that you are trying to run a hydraulic top link on a tractor that has automatic draft control engaged. Those two systems can work against each other with tremendous power. If that's the case, I'm not surprised it will break things like shown.

Be sure to turn off the automatic draft control and lock the top link attachment point before using a hydraulic top link.

tacticalturnip

Elite Member

Is there another lever right next to your 3 point lift lever?

Yes, those I do know how to operate, but I rarely use them. It’s I usually just put the implement in the float position. Is there something I should or shouldn’t be doing with these levers when using a hydraulic top link? I do often lift or lower both levers at once.Is there another lever right next to your 3 point lift lever?

Last edited:

CalG

Super Member

- Joined

- Sep 29, 2011

- Messages

- 5,553

- Location

- vermont

- Tractor

- Hurlimann 435, Fordson E27n, Bolens HT-23, Kubota B7200, Kubota B2601

Could it be an issue with the o-rings?

If the flange surfaces are held apart by misplaced o-rings while the component is bolted down, some bad things could happen.

Else wise, it's a case of hydraulic pressure exceeding the design strength of that part.

Does you control valve for the top link have an over pressure return to tank line?

on review of the parts blow up, it does not appear that that mounting flange sees any hydraulic pressure. It only serves to mount the valve assembly to the tractor.

Something must be running into the valve body . Hoses? fittings? or some element on the 3pt lift arms?

You are going to need to look closely as the range of top link and lift arm positions are in operation.

It appears to be "metal to metal" failure.

An irresistible force, meeting an immovable object! ;-)

If the flange surfaces are held apart by misplaced o-rings while the component is bolted down, some bad things could happen.

Else wise, it's a case of hydraulic pressure exceeding the design strength of that part.

Does you control valve for the top link have an over pressure return to tank line?

on review of the parts blow up, it does not appear that that mounting flange sees any hydraulic pressure. It only serves to mount the valve assembly to the tractor.

Something must be running into the valve body . Hoses? fittings? or some element on the 3pt lift arms?

You are going to need to look closely as the range of top link and lift arm positions are in operation.

It appears to be "metal to metal" failure.

An irresistible force, meeting an immovable object! ;-)

Last edited:

So I don’t know if there is an over pressure return to tank line. I can tell you the working PSI of the top link is 3,000 PSI and is rated for tractors 45-90 hp, mine is a 75hp tractor. This question did get my wheels turning and I ran out side and put the top link back on. The cylinder will come into contact with the lower remote valves if it’s in the top hole. I don’t think it’s enough contact to actually break the piece though. I would think the remote valve would break first right? There’s no sign of contact on the valve body, but I could be wrong. The last time this piece broke the top link was in the top hole again. Prior to hooking up the no-till it was in the bottom hole where I used a sprayer and 4 row 3 point corn planter with no issues. Could operating draft control and the hydraulic remote at the same time cause this? I’m pretty quick with levers when I’m lifting and making a turn, and sometimes I grab the draft control lever and the 3pt lift lever at the same time.Could it be an issue with the o-rings?

If the flange surfaces are held apart by misplaced o-rings while the component is bolted down, some bad things could happen.

Else wise, it's a case of hydraulic pressure exceeding the design strength of that part.

Does you control valve for the top link have an over pressure return to tank line?

on review of the parts blow up, it does not appear that that mounting flange sees any hydraulic pressure. It only serves to mount the valve assembly to the tractor.

Something must be running into the valve body . Hoses? fittings? or some element on the 3pt lift arms?

You are going to need to look closely as the range of top link and lift arm positions are in operation.

It appears to be "metal to metal" failure.

An irresistible force, meeting an immovable object! ;-)

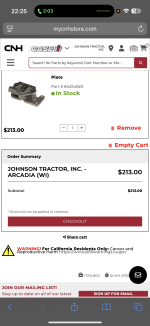

Attachments

CalG

Super Member

- Joined

- Sep 29, 2011

- Messages

- 5,553

- Location

- vermont

- Tractor

- Hurlimann 435, Fordson E27n, Bolens HT-23, Kubota B7200, Kubota B2601

Great pics, but without the hydro-top link in place, I can only guess.

My guess is "Hoses fittings and couplers".

Might want to look into the positioning of those lower remotes, or put a bit of an extension on that top link cylinder .

Two things trying to occupy the same space at the same time.

Can you spin the hydro top link end for end and gain anything?

My guess is "Hoses fittings and couplers".

Might want to look into the positioning of those lower remotes, or put a bit of an extension on that top link cylinder .

Two things trying to occupy the same space at the same time.

Can you spin the hydro top link end for end and gain anything?

LouNY

Super Star Member

- Joined

- Jul 4, 2015

- Messages

- 11,931

- Location

- Greenwich, NY

- Tractor

- Branson 8050, IH 574, Oliver 1550 Diesel Utility (traded in on Branson) NH 8160. Kioti CK2620SECH

It is mechanical interference. Can you can move the hydraulic top link through it's travel with no binding?

Then with an implement attached that causes issues run the lift arms through their complete travel range and cycle the top link through it's entire range at all lift heights.

My first guess would be that with the top link retracted when the implement lift is traveled it is getting into a bind on the tractor end of the clevis.

Then with an implement attached that causes issues run the lift arms through their complete travel range and cycle the top link through it's entire range at all lift heights.

My first guess would be that with the top link retracted when the implement lift is traveled it is getting into a bind on the tractor end of the clevis.

Yes, the top link does not bind. I’m about 99% sure Calg is correct and it made contact with the remote valves. I ran it for a while off of the bottom hole prior to this and had no issues. Later on yesterday I moved it to the top hole to use with my no-till drill. When the cylinder is in the top hole it can touch the remote valves, not much but I think enough that it would crack the assembly plate since it’s just 5/16” cast.