Last set I did was a couple of years ago, I made an alignment jig by welding a section of old bed frame together that fit snugly against the rims, after replacement I just used the jig to set the wheels exactly where they were prior to repair.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Changing dust boot on tie rod - MX5100

- Thread starter Herkypilot

- Start date

- Views: 14334

-

- Tags

- kubota mx5100

More options

Who Replied?

/ Changing dust boot on tie rod - MX5100

#11

It happens. As others have said count the exposed threads and measure when done. I back the nit off a bit and then put a block of wood under and give it a love tap with ha mallet to get the end out. Where this is new you should have no problems.

On the new larger masseys they put the steering stuff behind the front axle. I wish knots would have done that.

On the new larger masseys they put the steering stuff behind the front axle. I wish knots would have done that.

Herkypilot

Platinum Member

- Joined

- Oct 3, 2011

- Messages

- 566

- Location

- Meadows of Dan, VA

- Tractor

- Kubota M7060 HDC12, KX040 & L3540 HST

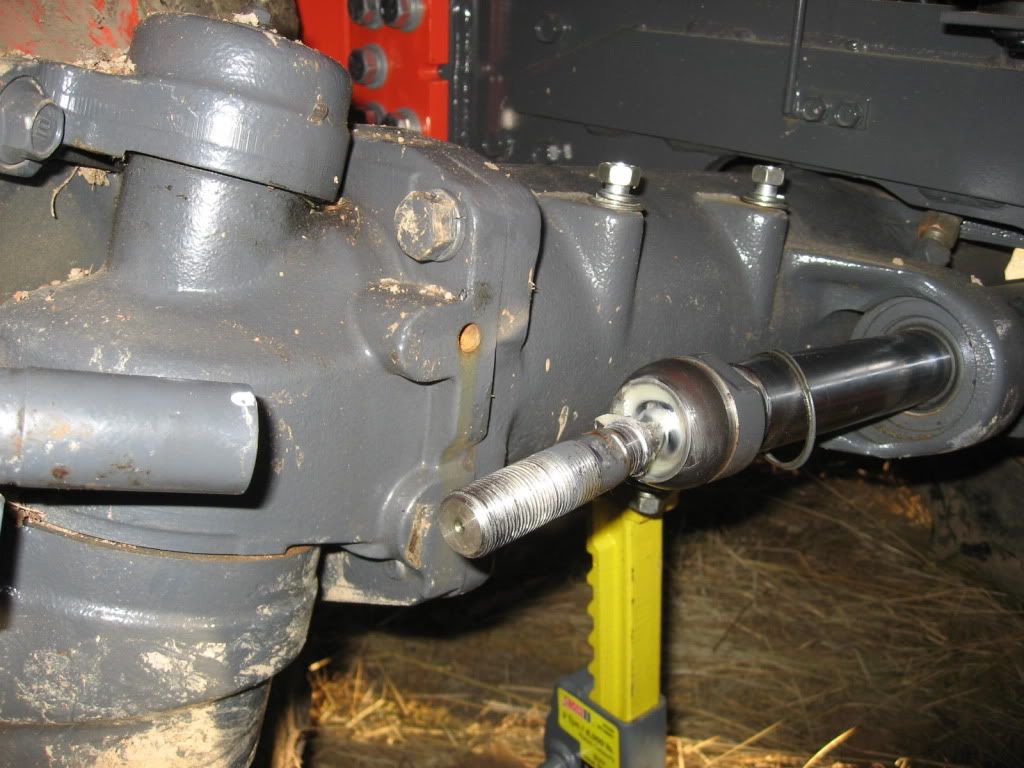

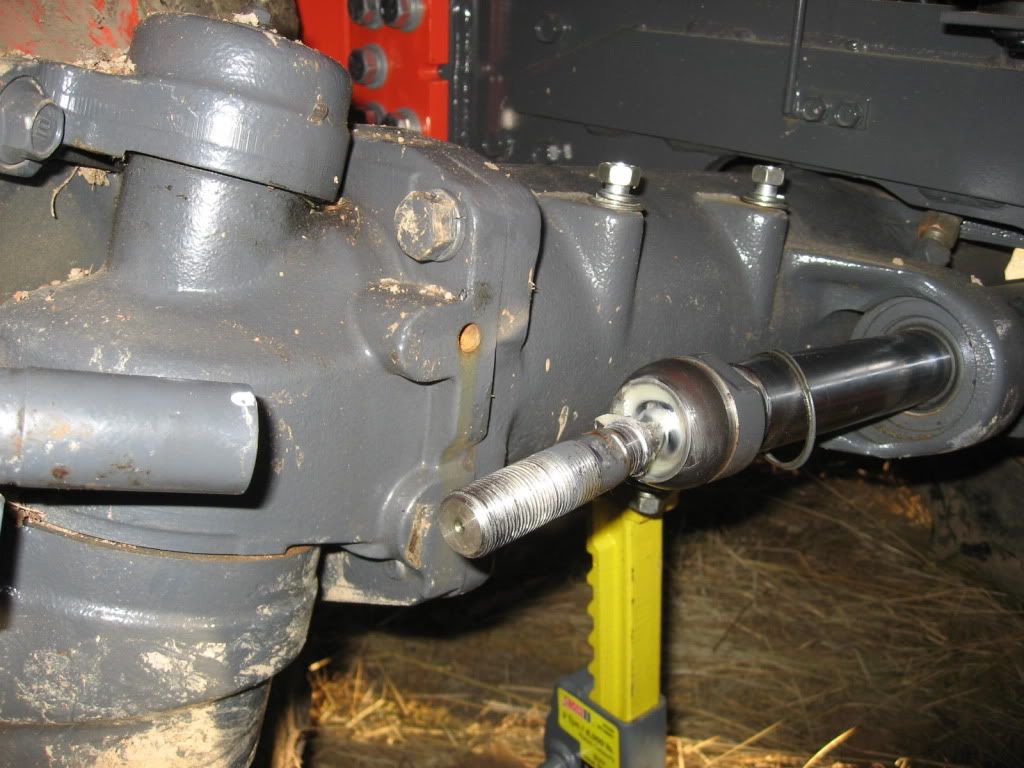

I finished the repair this weekend. Posting a few photos. I used the loader to raise the front and put a jack stand under the axle on the repair side only. No need to take off the tie rod completely. Just loosen the jam nut and the threaded end unscrews from the fitting. After that, taking the old boot off and putting on a new one is pretty easy. The retaining ring on the engine side is a bit of a pain. Use some of the lube from the joint and it will eventually slip on. I used a permanent marker to mark the threads before unscrewing. Just getting it within a thread of proper alinement. With R1 tires and a low speed vehicle off road, you won't know the difference.

Cheers,

HP

Cheers,

HP