Mike K2

New member

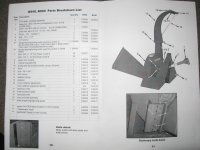

Hello all, I am a newcomer to tractoring and have a question about a used Wallenstein BX 40 chipper that I've been trying to use. There is of course no manual.

When chipping branches up to around 2" everything is OK. But when I try something near it's rated capacity of 4" the shear pin shears. I've gone through 3 pins in less than an hour's work.

The first question that I have is what are the shear pins supposed to be made of? I've been trying to play it safe by using grade 3 (no lines) 5/16-18 bolts that are mild steel.

The second question is what is the procedure for setting the blade clearance? I read that it should be 1/32 to 1/16" but I don't know where that is to be measured at. The chipper seems very aggressive and whacks off about 1/2" per blade. Could that be too much? Does blade clearance effect chip thickness or is it determined by the amount that the blades protrude through the disc?

Any suggestions would be appreciated.

When chipping branches up to around 2" everything is OK. But when I try something near it's rated capacity of 4" the shear pin shears. I've gone through 3 pins in less than an hour's work.

The first question that I have is what are the shear pins supposed to be made of? I've been trying to play it safe by using grade 3 (no lines) 5/16-18 bolts that are mild steel.

The second question is what is the procedure for setting the blade clearance? I read that it should be 1/32 to 1/16" but I don't know where that is to be measured at. The chipper seems very aggressive and whacks off about 1/2" per blade. Could that be too much? Does blade clearance effect chip thickness or is it determined by the amount that the blades protrude through the disc?

Any suggestions would be appreciated.