patrickg

Veteran Member

I have a 20 ton hydraulic shop press. And real soon now I will have more pears than I can eat or easily give away (9 really large old, 100 yrs?) pear trees. I like cooked pears, pear butter, pear sauce (if you do it with apples I can do it with my pears as they are crisp and firm fleshed, not soft llike a bartlet) They are very sweet and juicy and should make good juice/cider.

I was thinking of, at least, temporarily replacing the 20 ton hand pumped bottle jack that powers my press with a air powered jack or a ram connected possibly to the remote hydraulics on the Kubota L4610 to lessen the manual labor that would be required to pump the handle about 127.382 kadrilion jilion times to make several galons of juice.

I have a good handle on how to make the fruit press attachment for the press as far as the "platten" and container with holes to let the juice out. Lots of info on cider presses available and I can duplicate for pear squeezing. No recommendations were noted for hydraulic rams or air powered jacks with appropriately long throw. I'm guessing that for conveninece at least a foot of throw would be good (many many pumps for a HD jack's handle).

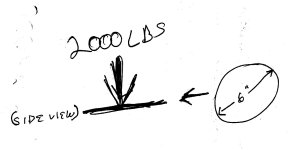

I guess I'm missing two kinds of info. I don't know how many PSI is required as a minimum which prevents me building the "squeeze box?". Once I know the PSI requirement, and have the force available from the ram/jack whatever, I can compute the max area of the "platten" and get started cutting, grinding, welding, grinding, etc. And I don't know what sort of specs and asvailability there is for for economical rams or air jacks. To not overstress the frame of the press, I don't think I should exceed the 20 tons it was designed for by much if any.

Any suggestions?

Patrick

I was thinking of, at least, temporarily replacing the 20 ton hand pumped bottle jack that powers my press with a air powered jack or a ram connected possibly to the remote hydraulics on the Kubota L4610 to lessen the manual labor that would be required to pump the handle about 127.382 kadrilion jilion times to make several galons of juice.

I have a good handle on how to make the fruit press attachment for the press as far as the "platten" and container with holes to let the juice out. Lots of info on cider presses available and I can duplicate for pear squeezing. No recommendations were noted for hydraulic rams or air powered jacks with appropriately long throw. I'm guessing that for conveninece at least a foot of throw would be good (many many pumps for a HD jack's handle).

I guess I'm missing two kinds of info. I don't know how many PSI is required as a minimum which prevents me building the "squeeze box?". Once I know the PSI requirement, and have the force available from the ram/jack whatever, I can compute the max area of the "platten" and get started cutting, grinding, welding, grinding, etc. And I don't know what sort of specs and asvailability there is for for economical rams or air jacks. To not overstress the frame of the press, I don't think I should exceed the 20 tons it was designed for by much if any.

Any suggestions?

Patrick