RegL

Platinum Member

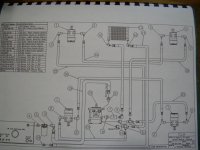

Several of us have been posting, for a couple of years now, about working the PT in hot weather and how when the oil gets hot it's less efficient and the tractor loses traction and power. And we have discussed better cooling methods and adding thermometers to the hydraulic tank.

Now I'm reading posts that the tram circuit is closed loop and the oil never gets back to the tank or through the cooler. If that's true it looks like we would need to add some kind of cooler just for the tram circuit. Maybe just fill the bottom of the tub up with ice cubes before we go mowing, lol.

Also , if the above is true, wouldn't the oil in the tank get overheated only by heavy pto use? To the contrary, I have made the tank to hot to touch by doing a lot of tramming. For instance, moving lots of brush long distances with the grapple bucket. What are some thoughts?

Now I'm reading posts that the tram circuit is closed loop and the oil never gets back to the tank or through the cooler. If that's true it looks like we would need to add some kind of cooler just for the tram circuit. Maybe just fill the bottom of the tub up with ice cubes before we go mowing, lol.

Also , if the above is true, wouldn't the oil in the tank get overheated only by heavy pto use? To the contrary, I have made the tank to hot to touch by doing a lot of tramming. For instance, moving lots of brush long distances with the grapple bucket. What are some thoughts?