You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Container Weld Shop build -

- Thread starter BukitCase

- Start date

- Views: 107470

More options

Who Replied?

/ Container Weld Shop build -

#231

("I gave up tryin' to figger THAT part out for the 1 ton version I'll be doing, so I just planned on TWO trolleys - one centered over each pair of mounting holes on the hoist - that way there'll be a trolley supporting the cable spool, and one for the motor. (That 1 tonner is a LOT bigger than the 440# one, right at TWICE as long AND TWICE as wide, plus instead of maybe 23 lbs it's more like 75...")<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

The two trolley sounds the best idea, if I had some welding rods for wood, I'd add two more feet of I beam to my wooden I beam. Reason 110 why I like working with steel instead of wood, usually when I work with wood I cut a 2x4 three times and it's still comes out to short.

The two trolley sounds the best idea, if I had some welding rods for wood, I'd add two more feet of I beam to my wooden I beam. Reason 110 why I like working with steel instead of wood, usually when I work with wood I cut a 2x4 three times and it's still comes out to short.

OP

BukitCase

Elite Member

- Joined

- Feb 17, 2012

- Messages

- 2,756

- Location

- Albany OR

- Tractor

- Case 580B, Long 460, Allis-Chalmers 160

Know whatcha mean, somehow I cut just ONE of the cross pieces (2" square tube x 1/8" wall - see, I CAN use "normal ruler stuff" too :=) on my container roof 1/4" too short, ended up cuttin' about 1/8" off another piece, leaving a small "open root" gap at both ends, and welding it back up - worked MUCH better than fixin' the SAME boo-boo on WOOD...

Too bad you don't need ANOTHER 10' jib somewhere else, you could pick up a 20' stick of 5" x 10 lb. I beam for about $150, cut it in half and stop messin' with the wood one - that size would MORE than do for anything up to at least 1000 lbs (at 10' long, anyway) - it'd probly tear your swivel mount off the wall before the beam would care... Steve

Too bad you don't need ANOTHER 10' jib somewhere else, you could pick up a 20' stick of 5" x 10 lb. I beam for about $150, cut it in half and stop messin' with the wood one - that size would MORE than do for anything up to at least 1000 lbs (at 10' long, anyway) - it'd probly tear your swivel mount off the wall before the beam would care... Steve

("Too bad you don't need ANOTHER 10' jib somewhere else, you could pick up a 20' stick of 5" x 10 lb. I beam for about $150")

I aventually as in sooner than later want to put a Jib crane inside my shop, but steel cheaper then wood? (cough cough, roll my eyes, scratch my head) time for a math lesson using my state the art calculator, 1st I have plenty of wood, I can go down back cut a log bring it out in 3 hr with 2 gal of tractor fuel, mill it up 4 hr with 1 gal of gas, stack and sticker upstairs in my garage 4 hr, wait for it to dry 3 summer months, make a 16' I beam in 24 hr with using $50.00 worth of glues screws and paint, 24 hr to let paint dry and wahla a 16' ft wooden I beam all for under $60.00.

PS I was bored and wanted to wright something and check your funny bone using alternative facts.

I aventually as in sooner than later want to put a Jib crane inside my shop, but steel cheaper then wood? (cough cough, roll my eyes, scratch my head) time for a math lesson using my state the art calculator, 1st I have plenty of wood, I can go down back cut a log bring it out in 3 hr with 2 gal of tractor fuel, mill it up 4 hr with 1 gal of gas, stack and sticker upstairs in my garage 4 hr, wait for it to dry 3 summer months, make a 16' I beam in 24 hr with using $50.00 worth of glues screws and paint, 24 hr to let paint dry and wahla a 16' ft wooden I beam all for under $60.00.

PS I was bored and wanted to wright something and check your funny bone using alternative facts.

OP

BukitCase

Elite Member

- Joined

- Feb 17, 2012

- Messages

- 2,756

- Location

- Albany OR

- Tractor

- Case 580B, Long 460, Allis-Chalmers 160

My funny bone still seems to work, but I HAVE noticed it's a bit more "creaky" than it useta wuz

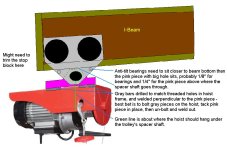

Forgot to mention before - that small 440# hoist isn't LONG enough to have room to use TWO trolleys - but there MIGHT be a way to add a couple different mounts to the trolley so ONE pair of wheels was almost centered over the spool and the OTHER pair centered over the motor - I'll play around with that idea a bit, see if it holds water (er, I mean firewood

Got more drawing done last night, gettin' close to cutting parts for the "wide-track post braces" on the HF crane... Steve

Forgot to mention before - that small 440# hoist isn't LONG enough to have room to use TWO trolleys - but there MIGHT be a way to add a couple different mounts to the trolley so ONE pair of wheels was almost centered over the spool and the OTHER pair centered over the motor - I'll play around with that idea a bit, see if it holds water (er, I mean firewood

Got more drawing done last night, gettin' close to cutting parts for the "wide-track post braces" on the HF crane... Steve

OP

BukitCase

Elite Member

- Joined

- Feb 17, 2012

- Messages

- 2,756

- Location

- Albany OR

- Tractor

- Case 580B, Long 460, Allis-Chalmers 160

Got most of the parts cut today for the post braces on the HF crane - still need to cut 4 pieces of 2" x 1/8" wall tubing for the diagonals, they'll be 31" point to point, both ends cut 45*. Here's what I got done today, got some more prep to do on most of 'em -

This batch is for the crane braces, all just out of the saw. I'll need to notch 2 of the channel pieces to clear the diagonal square tubes, other ends will come in on the FLAT side -

And these are most of the NEW "porch roof" plan - decided against doing a full-fledged roof frame out of 2" tubing, so these will each get a 10' piece of tubing slid thru the shiny pieces (they're actual .030" over RECEIVER tubing) - then I'll just strap a 9x11 tarp over the long tubing pieces and it'll hang over the doors of the container by about 7 feet. One less "permanent" project for a "temporary" condition :thumbsup:

Guess tomorrow (and probably the next day or two after) will be clean up/weld up/put up time (for the "porch roof", that is - the braces will likely take longer... Steve

This batch is for the crane braces, all just out of the saw. I'll need to notch 2 of the channel pieces to clear the diagonal square tubes, other ends will come in on the FLAT side -

And these are most of the NEW "porch roof" plan - decided against doing a full-fledged roof frame out of 2" tubing, so these will each get a 10' piece of tubing slid thru the shiny pieces (they're actual .030" over RECEIVER tubing) - then I'll just strap a 9x11 tarp over the long tubing pieces and it'll hang over the doors of the container by about 7 feet. One less "permanent" project for a "temporary" condition :thumbsup:

Guess tomorrow (and probably the next day or two after) will be clean up/weld up/put up time (for the "porch roof", that is - the braces will likely take longer... Steve

dragoneggs

Super Star Member

- Joined

- Jun 9, 2013

- Messages

- 14,548

- Location

- Seabeck, Washington

- Tractor

- Kubota BX-25D, Kubota Z122RKW-42

Thanks for all the detail, Steve!

OP

BukitCase

Elite Member

- Joined

- Feb 17, 2012

- Messages

- 2,756

- Location

- Albany OR

- Tractor

- Case 580B, Long 460, Allis-Chalmers 160

You're welcome Mark - you probably caught the visual proof (first pic in that last post) of my belief in the old adage, "A clean desk is a sign of a sick mind" - :laughing: ...Steve

OP

BukitCase

Elite Member

- Joined

- Feb 17, 2012

- Messages

- 2,756

- Location

- Albany OR

- Tractor

- Case 580B, Long 460, Allis-Chalmers 160

Most of the time I use a Walter zip disk (light touch, constant movement, about a 45* angle) if there's mill scale - then smooth it out with a CGW 40 grit flap disk (same method as the zip disk, only almost flat) - a NEW 40 grit is a little aggressive, so I use NEW ones for bevels, etc, til they "mellow out" a bit, then I use them for the "final shiney" part -

If a part has sat long enough to start a light rust coat before I get around to finishing the job, I have an old B&D "professional" high speed corded drill (came as a 1/4", I put a 3/8 keyless chuck on it) - it runs 4000 rpm, usually keep a 6" wire wheel on it and use it to get REALLY light rust off and add a bit of "tooth" before painting.

There's so much rain and humidity here a lot of the year, if I DON'T do that EVERYTHING is the SAME COLOR (reddish brown) and has its own "non-skid" finish

My favorite "bb blaster", for FLAT surfaces anyway, is an air hammer with a wide flat chisel, kept pretty sharp - you can just PUSH it along (low angle) til it stops on a more stubborn "bb", then just touch the trigger. That also works really good on the light slag after plasma cuts.

Small needle scaler for corners, fillets, etc...

If there's quite a bit of "flat land", this

Ingersoll Rand 315 Heavy Duty Air Twin Piston Straight Line Sander - 2-3/4-Inch x 17-1/2-Inch Pad - Power Random Orbit Sanders - Amazon.com

works pretty good too - I quit tryin' to live with plain-backed paper, now I buy the pressure-sensitive stuff in 40 grit. I got the idea from my GOOD neighbor, he runs a custom car shop next door. Side benefit - I can drool over all kinds of fun toys without havin' to use perfectly good TOOL money to do it :thumbsup::thumbsup::thumbsup:

I got the rest of the pieces cut (no pics yet) for both the "porch roof" on the container, AND the other tubing pieces for the HF crane's corner braces; might get more "shinifyin'" done after supper, I wanna get the "porch roof" part done (welded and painted) so I can keep the (coming soon,AGAIN) horizontal rain outa the weld shop container with the doors open... Steve

Oh, BTW - now you can join the "pick on Shiny Steve" club, Terry (Big Barn) is prez, but I'm pretty sure the "Veep" slot is still open :laughing:

If a part has sat long enough to start a light rust coat before I get around to finishing the job, I have an old B&D "professional" high speed corded drill (came as a 1/4", I put a 3/8 keyless chuck on it) - it runs 4000 rpm, usually keep a 6" wire wheel on it and use it to get REALLY light rust off and add a bit of "tooth" before painting.

There's so much rain and humidity here a lot of the year, if I DON'T do that EVERYTHING is the SAME COLOR (reddish brown) and has its own "non-skid" finish

My favorite "bb blaster", for FLAT surfaces anyway, is an air hammer with a wide flat chisel, kept pretty sharp - you can just PUSH it along (low angle) til it stops on a more stubborn "bb", then just touch the trigger. That also works really good on the light slag after plasma cuts.

Small needle scaler for corners, fillets, etc...

If there's quite a bit of "flat land", this

Ingersoll Rand 315 Heavy Duty Air Twin Piston Straight Line Sander - 2-3/4-Inch x 17-1/2-Inch Pad - Power Random Orbit Sanders - Amazon.com

works pretty good too - I quit tryin' to live with plain-backed paper, now I buy the pressure-sensitive stuff in 40 grit. I got the idea from my GOOD neighbor, he runs a custom car shop next door. Side benefit - I can drool over all kinds of fun toys without havin' to use perfectly good TOOL money to do it :thumbsup::thumbsup::thumbsup:

I got the rest of the pieces cut (no pics yet) for both the "porch roof" on the container, AND the other tubing pieces for the HF crane's corner braces; might get more "shinifyin'" done after supper, I wanna get the "porch roof" part done (welded and painted) so I can keep the (coming soon,AGAIN) horizontal rain outa the weld shop container with the doors open... Steve

Oh, BTW - now you can join the "pick on Shiny Steve" club, Terry (Big Barn) is prez, but I'm pretty sure the "Veep" slot is still open :laughing: