Phil Timmons

Silver Member

- Joined

- Mar 18, 2008

- Messages

- 111

I suppose most here are familiar with various designs using batteries. However, these have some limitations of expense, weight, limited service life, and run and charge times.

A way to avoid the battery issues is to use Grid-Connected designs. This allows the Grid-Connected equipment unlimited run time, longer service life, as well as no battery related expense.

Have worked out some Center-Pivot style Electric Designs. Those are fairly easy, as the Center of the Pivot has an Electric Supply, and electric drive wheels all the way down the towers -- so this provides Grid-Connected electricity to the entire field.

But when you get into irregular field shapes, things can get a bit more complex. Looking at using Cord Connections for these, and looking at the Cord Management involved.

John Deere has their approach shown here >>>

However, their approach -- with a kilometer of cord, and the complex reel system adds about as much expense as batteries.

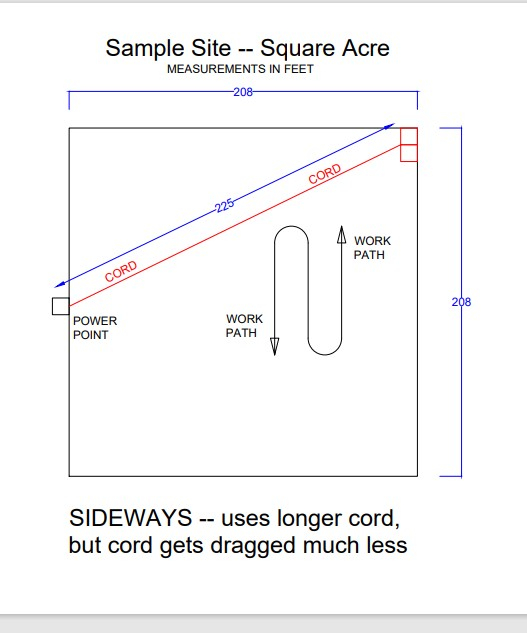

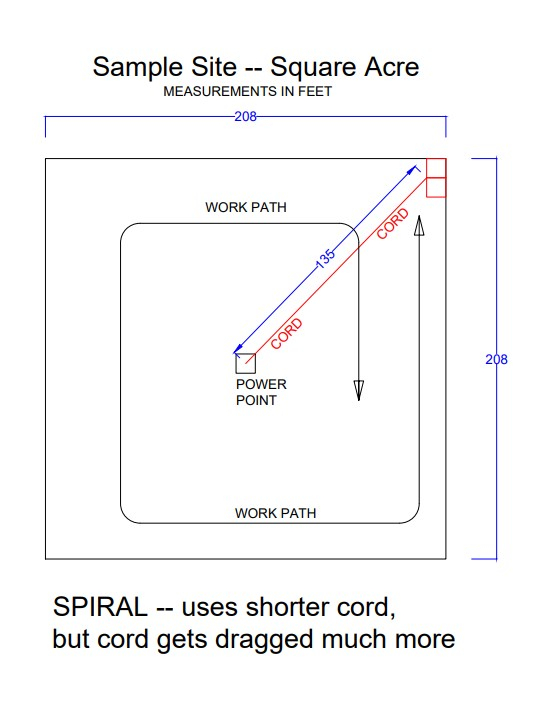

One approach is to use a side-of-the-field connection approach, and allow the cord to sweep along beside the equipment while you work your way across the field, and another approach is to use a center-of-the field connection approach and spiral in or out from this center.

Attached are a couple of very simplified sketches on a sample one acre square. Of course, practical irregular field sites would have more complex geometry than this. Major goals are to NEVER run over the cord, prevent damage from objects to the cord, and how to cover the field space (the pattern) to function in a safe and efficient manner.

Was wondering what anyone might have as far as clever ideas, insights etc. Maybe other than OMG! Do Not Do This! Joking -- if you do see cause for OMG-Do-Not-Do-This -- chime in, too.

Joking -- if you do see cause for OMG-Do-Not-Do-This -- chime in, too.

Expected Voltages will likely be US 480V 3 Phase -- with about 10 to 100 HP at the mobile equipment end. Equipment will likely have SMALL batteries on board for transit between field sites and in-and-out of the barn without a cord connection. Cords I have used on test runs are TC - Tray Cable wiring, with and without PVC coated seal-tite to prevent damage. So far, this has worked well, but if anyone has other and/or hopefully better suggestions on cord, that is welcome, as well.

Thanks!

A way to avoid the battery issues is to use Grid-Connected designs. This allows the Grid-Connected equipment unlimited run time, longer service life, as well as no battery related expense.

Have worked out some Center-Pivot style Electric Designs. Those are fairly easy, as the Center of the Pivot has an Electric Supply, and electric drive wheels all the way down the towers -- so this provides Grid-Connected electricity to the entire field.

But when you get into irregular field shapes, things can get a bit more complex. Looking at using Cord Connections for these, and looking at the Cord Management involved.

John Deere has their approach shown here >>>

However, their approach -- with a kilometer of cord, and the complex reel system adds about as much expense as batteries.

One approach is to use a side-of-the-field connection approach, and allow the cord to sweep along beside the equipment while you work your way across the field, and another approach is to use a center-of-the field connection approach and spiral in or out from this center.

Attached are a couple of very simplified sketches on a sample one acre square. Of course, practical irregular field sites would have more complex geometry than this. Major goals are to NEVER run over the cord, prevent damage from objects to the cord, and how to cover the field space (the pattern) to function in a safe and efficient manner.

Was wondering what anyone might have as far as clever ideas, insights etc. Maybe other than OMG! Do Not Do This!

Expected Voltages will likely be US 480V 3 Phase -- with about 10 to 100 HP at the mobile equipment end. Equipment will likely have SMALL batteries on board for transit between field sites and in-and-out of the barn without a cord connection. Cords I have used on test runs are TC - Tray Cable wiring, with and without PVC coated seal-tite to prevent damage. So far, this has worked well, but if anyone has other and/or hopefully better suggestions on cord, that is welcome, as well.

Thanks!