Arc weld

Veteran Member

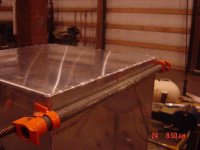

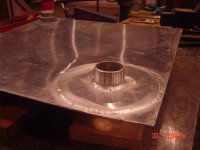

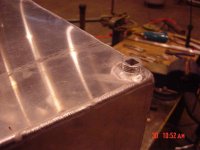

Make your cuts at least 1/16-inch big, then grind or sand to the dimension you want. If you Tig weld aluminum after plasma cutting this can happen.:thumbdown:

Don't know how to post a link but maybe you need to get some coke bottle glasses, move to the trailer park , ride around in a go cart and go by the name Bubbles.

The first time I was assigned to weld the top on, on a big oilfield tank with 6010, I had a few leaks on my section. There was another guy with the same name and they thought he just had a bad day. I knew better and he never said anything. You have to like guys like that. :thumbsup: Thankfully that's why they tests tanks and 31 leaks isn't so bad. :ashamed::ashamed: I would have been about 18 at the time, a few month's out of high school working in a bucket truck. It was relatively easy for the other welders to fix. I'm just glad I wasn't the one who was told to cut the temporary D rings (for lifting) off a tank. The poor guy that did, got them off alright except instead of saving the tank, he saved the D rings. He cut holes in the tank around where the D rings were welded on.