Good news is, the machine shop called me on Fri and verified that he found the crank to measure fine and will just polish, he said the cylinder head was in good shape too. Bottom line, under $400 for both. So I don't want to curse myself just yet, but with the rebuild kit, machine work, injectors new oil pump, and misc. I should have this thing rebuilt for around just under $2k, I can even afford to pay myself 50 cents an hour for tear down and assembly

I also asked the machine shop his thoughts about my measurement on the block and he said those numbers don't scare him at all... which I think we all sort of figured out, but its nice to hear it from a guy who does it everyday.

I am pretty sure the pistons are in correctly. The injector lines up with that square pocket between both round recesses. It is probably designed to create a bit of a swirl pattern.

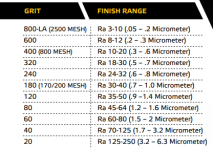

I did notice that chart indicated a better RA, but somewhere on their site, which is also copied on other retailers websites, it shows a higher RA.

Flex-hone, How to select the size, grit size and abrasive type, what size, grit and abrasive type Flexhone do I need or use? - Newman Tools

I am thinking after honing with the ball hone I will run some 1200 paper over it lightly or maybe a fine scotchbrite pad or similar, then wash with soap and water.