orangetree

Gold Member

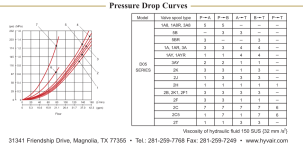

Hyvair style D03 (ISO 4401) size valves&manifolds seem in common use for small TLB applications (summit kits for rear remote & port multiplier, w.r.long 3rd function kits).

It seems that D03 spec valves are spec'd for ~16gpm or higher (plenty, my tractor has 7gpm)

But all the D03 manifolds are rated for 5gpm https://hyvair.com/hydraulic/manifolds-subplates/hyvair-standard-manifolds/, https://hyvair.com/hydraulic/manifolds-subplates/miniature-manifolds/

Thanks!

It seems that D03 spec valves are spec'd for ~16gpm or higher (plenty, my tractor has 7gpm)

But all the D03 manifolds are rated for 5gpm https://hyvair.com/hydraulic/manifolds-subplates/hyvair-standard-manifolds/, https://hyvair.com/hydraulic/manifolds-subplates/miniature-manifolds/

- Is the 5gpm per valve (probably just fine for my application) or is that for the power-beyond flow through the whole manifold?

- manifold plumbing: I assume (but cannot find a definitive answer) that each valve is in series, thus my open-center platform's PB flow flows through ALL valves in the block, in series, even if none are activated.

Thanks!