ok, rehashing my thread since it's time to start the build soon. Great feedback so far has led me to an update of my initial plans.

1. Changing from a forklift bin tipper to a standalone. I have figured it's going to be much more valuable to have the forklift available for other work.

2. This means a design change, but fundamentally keeping the same principal of where and how to tip.

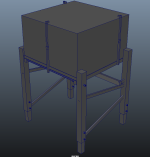

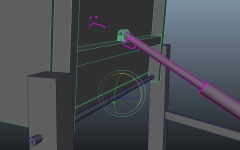

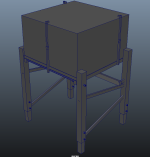

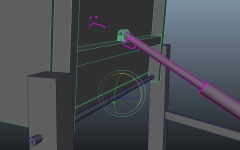

So design's attached. Couple things I'm wondering about are the design of the attachment points for the cylinder. I see this tipping over when the bin is tipping with the center of gravity moving so far forward. Wondering about either tapering the legs, or adding feet. Thoughts? Also the big question for me is steel sizing. I feel like I know a couple of things here. 1. Depth (not thickness) is probably the most important for resisting force 2. Thicker is better )but not for my wallet). Is there a good "depth plus thickness = strength" guideline?

couple of bits of info.

1. This design is based off a 27" pin to pin retracted length with an 18 inch stroke.

2. Design is to scale, and functions mechanically, so reconfigration is quick, and should show me accurate results / problems.

3. Telescoping legs for height adjustment.

4. Pivot point for the pin (long steel pipe through some bushings? pillow block bearing?)