I assume you read the previous posts concerning Radius Rods.john_bud said:GT2, Good progress.

Couple points. As you probably know, the radius rods are to prevent front to back motion of the front axle. It is important that you add them! Otherwise the front frame will be twisted to junk on the first pot hole, rock, stump or other obsticle you encounter.

I would also beef up the front frame (and side frame where the radius rods attach) to take up the extra stress. Then again, I would rather weld than repair!

Good looking project so far!

jb

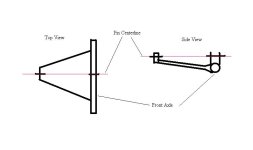

My concern is that since the axle cant twist now, radius rods will twist the axle during movement and cause cracks.

Now I can make the rods long and lower the rearward pivot point so it is level with the axle, to lessen the " twisting and steering" effect. But I'm not sure if its going to be enough.

What If I used rods that had only one pivot point at the axle. This would help resist fore and aft movement of the axle, but not twist it?

Of corse this design would not resist any axle torque twist.