anesthes

Bronze Member

I love this forum

I tried google, but didn't find exactly what I wanted.

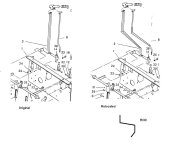

I have a 4 way loader valve. I want to re-do the controls and such on my machine. Right now I have sloppy and somewhat long linkage to the valve. I was curious if I could purchase something that is 12v that will pull or push the valve, that I could connect to a self centering rocker switch. I'd love to replace my handles with a nice pair of grips with a thumb rocker to operate the bucket and loader arms.

Pictures attached

I know I can replace the whole valve but I'd rather just add some sort of push/pull solenoid.

-- Joe

I tried google, but didn't find exactly what I wanted.

I have a 4 way loader valve. I want to re-do the controls and such on my machine. Right now I have sloppy and somewhat long linkage to the valve. I was curious if I could purchase something that is 12v that will pull or push the valve, that I could connect to a self centering rocker switch. I'd love to replace my handles with a nice pair of grips with a thumb rocker to operate the bucket and loader arms.

Pictures attached

I know I can replace the whole valve but I'd rather just add some sort of push/pull solenoid.

-- Joe