Wild Bill the 2nd

Gold Member

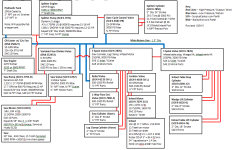

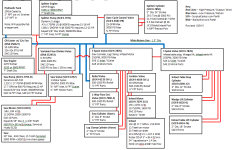

In the process of building a firewood processor (main post here) I am about to pull the trigger on about $3000 of equipment and wanted to post this diagram to see if anyone sees anything that doesn't look right.

The main questions I have are on the saw side of things. I am following the recommendations that Danzco lays out for their saws but I like to double check things.

I have a 22HP Kohler out of a lawn tractor that I'm planing to run a 1.22ci 17 GPM pump.

17 GPM at 900 PSI requires about 22 HP

Is there anything I need to do to keep the pressure down around 900 PSi? As long as I don't push things too hard too fast pressure shouldn't build past that point correct?

My assumptions are as follows:

Husquevarna 3120 Specs .404 chain, 7 tooth sprocket, 8.4 HP, 9000 RPM, 4,242 Ft/Min chain speed

8.4 HP @ 9000 RPM = 4.9 ft/lb or 59 in/lb

.58 ci saw motor at 650 PSI = 60 in/lb

That would leave 250 PSI of headroom.

I have an adjustable priority flow divider valve in place after the pump to direct the majority of the fluid to the saw but then direct some fluid to the remaining system (except for the splitter, that has its own engine and pump). The only thing that I would do on the circuit while sawing is to advance the saw through the log. I am worried about driving the saw to fast into the log and stalling out the motor. I put an adjustable relief valve (only found 500 PSI though) to keep pressure down and then put a 1-way flow control valve inline after that. Overkill?

I think the last thing is the hydraulic tank size. The saw motor will run 17 GPM and the splitter will run 28 GPM in the HI flow mode. Does that mean I really need 50 gal of fluid? I'm thinking I would put an oil cooler on the thing. Could that keep me down a little bit or no?

Thanks for the help!

The main questions I have are on the saw side of things. I am following the recommendations that Danzco lays out for their saws but I like to double check things.

I have a 22HP Kohler out of a lawn tractor that I'm planing to run a 1.22ci 17 GPM pump.

17 GPM at 900 PSI requires about 22 HP

Is there anything I need to do to keep the pressure down around 900 PSi? As long as I don't push things too hard too fast pressure shouldn't build past that point correct?

My assumptions are as follows:

Husquevarna 3120 Specs .404 chain, 7 tooth sprocket, 8.4 HP, 9000 RPM, 4,242 Ft/Min chain speed

8.4 HP @ 9000 RPM = 4.9 ft/lb or 59 in/lb

.58 ci saw motor at 650 PSI = 60 in/lb

That would leave 250 PSI of headroom.

I have an adjustable priority flow divider valve in place after the pump to direct the majority of the fluid to the saw but then direct some fluid to the remaining system (except for the splitter, that has its own engine and pump). The only thing that I would do on the circuit while sawing is to advance the saw through the log. I am worried about driving the saw to fast into the log and stalling out the motor. I put an adjustable relief valve (only found 500 PSI though) to keep pressure down and then put a 1-way flow control valve inline after that. Overkill?

I think the last thing is the hydraulic tank size. The saw motor will run 17 GPM and the splitter will run 28 GPM in the HI flow mode. Does that mean I really need 50 gal of fluid? I'm thinking I would put an oil cooler on the thing. Could that keep me down a little bit or no?

Thanks for the help!