EverythingAttachments

Elite Member

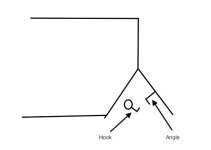

Here is the first look at our new Everything Attachments floating tailgate box blade.

A quick rundown of the details so far:

The first model that we've made is a 72". It weighs over 900 pounds!

Category 1&2 quick hitch compatible.

Extended sides on the rear, which will make backfilling easier.

Higher capacity than our current Severe Xtreme Boxblade.

Sizes will range from 72" up to 96".

Will be accepting orders in the next 1-2 weeks.

The introductory price for the 72" model will be $2,195 shipped to a commercial business or supporting freight terminal within 1,000 miles of Newton, NC.

More details, pics and product video coming soon!

Travis

A quick rundown of the details so far:

The first model that we've made is a 72". It weighs over 900 pounds!

Category 1&2 quick hitch compatible.

Extended sides on the rear, which will make backfilling easier.

Higher capacity than our current Severe Xtreme Boxblade.

Sizes will range from 72" up to 96".

Will be accepting orders in the next 1-2 weeks.

The introductory price for the 72" model will be $2,195 shipped to a commercial business or supporting freight terminal within 1,000 miles of Newton, NC.

More details, pics and product video coming soon!

Travis