Thanks for the help. So far all of the grease fittings have taken grease and everything is moving freely. I am currently missing 2,1,3 knives so I plan to make each one short 2 knives closest to the drive end until I can get new knives ordered in. There is still some rust on the sheaves that I will clean up before I test it. Hope to try it out in the yard one day this week.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ford 22-125 flail advice

- Thread starter Mallard1

- Start date

- Views: 10734

/ Ford 22-125 flail advice

#11

I pulled the rods out the hold the knives in and put the two open links closest to the gear box. Everything spun good with very little vibration. It cut good in thinner grass however I cut some Bahia grass that was 18” tall and it slipped the old belt in first gear. My new belt should be in soon. When I actually go cut my food plots would I be better off to raise it up one hole on the rear roller vs being all the way down? Thanks.

leonz

Super Member

Hello Mallard,

If you raise it up one hole it will lower the cutting height if you have more mounting holes below

the current setting you can lower it one position and see how it mows.

When the rear roller is adjusted at the lowest mounting hole position it will be at its highest cutting height.

Start in the middle position and see how it mows. You may want to lower the cutting height by raising the

rear roller one position and try mowing again.

No worries we are here for you Mallard.

LeonZ

If you raise it up one hole it will lower the cutting height if you have more mounting holes below

the current setting you can lower it one position and see how it mows.

When the rear roller is adjusted at the lowest mounting hole position it will be at its highest cutting height.

Start in the middle position and see how it mows. You may want to lower the cutting height by raising the

rear roller one position and try mowing again.

No worries we are here for you Mallard.

LeonZ

Thanks Leon, I guess I worded that incorrectly, it is currently in the top hole giving it the lowest cutting height. It is cutting maybe 2” from the ground. It only has three adjustment holes so that is my plan to move it to the middle height.

My flail is also missing the rear deflector. I know from a safety standpoint it is needed but does it have any effect on cut quality?

My flail is also missing the rear deflector. I know from a safety standpoint it is needed but does it have any effect on cut quality?

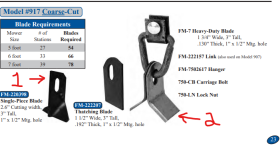

another question the the knifes, in the picture below i currently have the one on the left marked "1". would the one on the right marked "2" be better for mowing food plots and trails? what is the advantage of each. Sorry for all of the questions just trying to figure it all out. Thanks again for all of the help!

leonz

Super Member

Thanks Leon, I guess I worded that incorrectly, it is currently in the top hole giving it the lowest cutting height. It is cutting maybe 2” from the ground. It only has three adjustment holes so that is my plan to move it to the middle height.

My flail is also missing the rear deflector. I know from a safety standpoint it is needed but does it have any effect on cut quality?

(it is better that you have the deflector only because of the possibility that a knife my lift a rock up and out and hit a 2 or 4 legged rug rat or a car.

another question the the knifes, in the picture below i currently have the one on the left marked "1". would the one on the right marked "2" be better for mowing food plots and trails? what is the advantage of each. Sorry for all of the questions just trying to figure it all out. Thanks again for all of the help! View attachment 619580

The cut is something you will have to decide on Mallard, the scoop knives are a one and done affair. the side slicers will let you make a second or even third pass on the clippings to shred them even finer. The scoop knife was developed as a dual purpose mowing knife in that it could be used for mowing lawns and heavy brush.

The only decision will be whether you want to have brush laying down on the food plot or clippings that will dissolve quickly.

Happy Mowing

Fallon

Super Member

No effect on cut quality as tested when I cut out the dented part of my hood. It was messy though.Thanks Leon, I guess I worded that incorrectly, it is currently in the top hole giving it the lowest cutting height. It is cutting maybe 2” from the ground. It only has three adjustment holes so that is my plan to move it to the middle height.

My flail is also missing the rear deflector. I know from a safety standpoint it is needed but does it have any effect on cut quality?

My roller had been welded in place years or decades before I got it. I just adjusted cut height with the 3pt height rather than the roller height. Worked fine & I actually still do the same thing with my new Peruzzo. Much more convenient to do than messing with bolts. Just dont let the U-joint angle on the PTO shaft get to steep. The straighter the longer the U-joints will last.

View attachment 619644View attachment 619645

Last edited:

Fallon

Super Member

Heavier things win a fight thanks to basic physics. So the heavier a blade, the more likely it is to win a fight with a stick or a rock. For various definitions of win. You definitely want heavier blades for woody or brushy material so they impart more cutting force before bouncing.another question the the knifes, in the picture below i currently have the one on the left marked "1". would the one on the right marked "2" be better for mowing food plots and trails? what is the advantage of each. Sorry for all of the questions just trying to figure it all out. Thanks again for all of the help! View attachment 619580

I have side slicers on my 917, "2" according to your image. They cut woody brush up to finger size. When attempting to mow over branches or small trees 1-2" or so things would get noisy & it would just strip bark off. I'd imagine the duck foot (what you are calling "1") blades would do a bit better due to weight, but not that much better. My Peruzzo has 5lbs hammers that look basically like the duck foots. My tractor runs out of HP mowing wrist sized trees & branches while the mower is happily mulching away.

When mowing heavier brush, rocks or a well head, the lighter side slicers will just just bounce off without damage unless you jam things up really good. A heavier blade will have enough momentum to more likely damage itself. The 5lbs hammers start damaging the rocks & often taking little significant wear themselves.

The side slicers are plenty good for fields & pastures. They are also stupid cheap as its little more than light bar stock with a hole & a small bend in it. Way simpler & cheaper than the complex bending or welding required for a duck foot blade. Massively cheaper than my 5lbs cast hammers. Hitting the well wrecked 8ish side slicers & was under a $15 pain in the wallet (although I had old spares already).

I got my new knives put on this afternoon and made a few passes on the yard at the camp. It cut good but I noticed when I got done there was grass stuck to the top of the blades. I attached a picture to show this. It doesn’t appear to be wrapped on the bottom just the top. Also I noticed that I must have slipped the new belt some as the sides had some wear.