lostcreekranch

Super Member

- Joined

- Dec 14, 2012

- Messages

- 7,948

- Location

- Austin County, Texas

- Tractor

- NH TL-100A with Bush Hog 5045 FEL, WR Long 3rd function, LS XR4155HC w/FEL, WR Long 3rd Function.

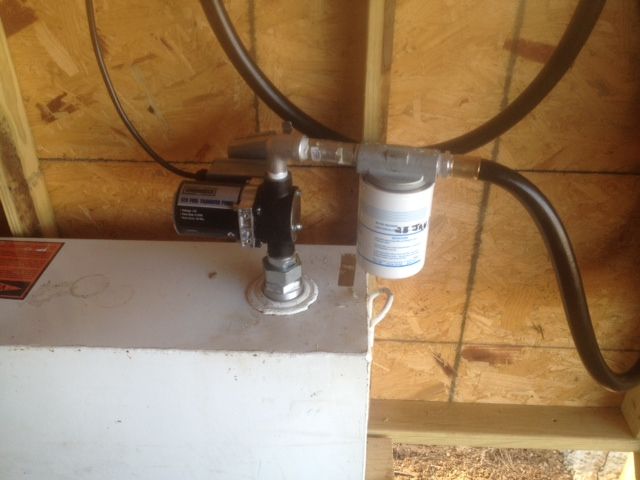

Do not use the lifting eyes on the ends of the tanks for moving a full tank. They are only for lifting an empty tank. There should be a sticker on the tank warning of that issue. If you try to lift a full tank, you run a very high risk of ripping the eyes from the tank creating a big hole in the tank. It should have some mounting pads on the bottom corners than you can mount it to a sturdy platform that can be lifted with pallet forks OR as I did with my 100 gallon rectangular tank, mount wheels on it for rolling it around on a concrete slab. For lifting, use appropriate sized straps or chains (2) ran under the tank for chokers then use the tractor FEL to lift it out. The wheels make it about 2.5-3" off the floor so it is easy to get straps around it. When putting your suction pipe in the tank for your pump, lift the pipe up about 2" off the bottom so you minimize any lifting of water condensate when pumping. You can also tip the tank an inch or so to the end with the drain plug is lower. Install a drain valve there and open it occasionally and catch a sample in a glass jar so you can check for water. If clear the sample can be poured back into the tank. You just need a close nipple (about 1" long), some Teflon tape and a brass valve to install it. DO this before you fill it the first time and you will be set. Filters are available at TSC and other farm supply places. You can use one with screw on filter like car oil filters or one with a canister that a filter fits in. Goldenrod makes this kind , Baldwin makes a screw on one. Either one is fine. The canister type usually has a clear housing that you can visually see if any water is in the sediment bowl which is nice to know. The filter assembly will cost you about 20-30 bucks depending on the type you get. You will need two pipe nipples to complete it. Depending on how the fuel comes out of the pump (top or side) you would need to put in at least one 90 ell if coming out the top to remove the stress on the fuel hose. One 90 ell would make it lay horizontal if the discharge is from the top which is good but 2 and it would lay vertical which is better for the hose.

I agree with Gary. The lift eyes ARE NOT designed to lift a full tank of fuel.