schmism

Super Member

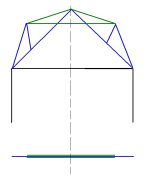

a design we did from time to time at the last place i worked (engineering truss designs)

went something like the attached.

there are some postitives and negitives

+

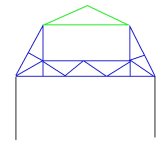

1) you can build it out of cheep 2x4 only trusses

2) easy to transport to site because its in pieces

-

1) requires feild assembly

2) requires 4 trusses

while it still requires more overall trusses they are easyer to handle individually and cheeper to make than one HUGE 36' truss

but you still have to supply LVL or some other material to support the floor.

The attached sketch is built with 4 trusses. 2 blue ones that make up the over all shape, and 2 green ones that overlap the blue ones at the top to provide an attachment as well as provide moment connection.

the 4 trusses are layed out at the site and attached then hoisted into place and set like tradtional trusses.

went something like the attached.

there are some postitives and negitives

+

1) you can build it out of cheep 2x4 only trusses

2) easy to transport to site because its in pieces

-

1) requires feild assembly

2) requires 4 trusses

while it still requires more overall trusses they are easyer to handle individually and cheeper to make than one HUGE 36' truss

but you still have to supply LVL or some other material to support the floor.

The attached sketch is built with 4 trusses. 2 blue ones that make up the over all shape, and 2 green ones that overlap the blue ones at the top to provide an attachment as well as provide moment connection.

the 4 trusses are layed out at the site and attached then hoisted into place and set like tradtional trusses.