eCRX

Bronze Member

- Joined

- May 25, 2016

- Messages

- 74

- Location

- Ayr

- Tractor

- 2004 Massey Ferguson GC2300, 2015 Cub Cadet XT2

I had all 3 control-to-tractor lines made new. got cocky and took all 3 lines off without labeling. figured the correct connections would be in the manual like they are for the FEL lines.

welp, the manual shows only 2 lines and the various parts diagram only confuse me more. I'm second guessing my memory because the new lines have longer metal sleeves and one of the lines seems slightly short. The icing on the cake is the lack of documentation from the nimco site. it's as if the 10339-2S never existed! I can usually get my geek on and get out of a jam like this by reading documentation, but I just can't get the info I need.

controller is Nimco 10339-2S

I did some searching and have determined that some GC2300 have been 'upgraded' throughout their life with a 3rd power-beyond line. later models included this from the factory.

anyway, I can narrow my question down to these two questions:

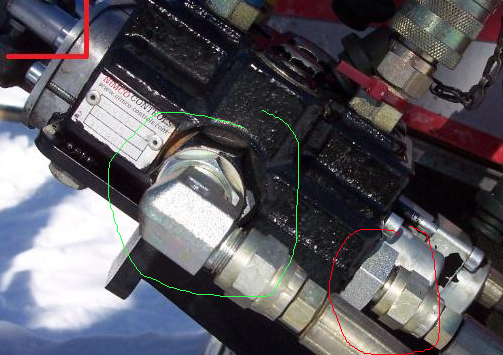

- can anyone confirm where this side-port (Green) line goes to?

- can anyone confirm that the red port goes to a 90deg elbow on the back of the tractor?

also, what are the consequences of guessing? I imagine either no control (fluid going strait to tank, or pressure side hooked up to tank side), triggering the relief valve on start-up, or weird control issues... but i'm not sure if one of those scenarios will damage something or myself

(Barrowed a pic from another thread)

welp, the manual shows only 2 lines and the various parts diagram only confuse me more. I'm second guessing my memory because the new lines have longer metal sleeves and one of the lines seems slightly short. The icing on the cake is the lack of documentation from the nimco site. it's as if the 10339-2S never existed! I can usually get my geek on and get out of a jam like this by reading documentation, but I just can't get the info I need.

controller is Nimco 10339-2S

I did some searching and have determined that some GC2300 have been 'upgraded' throughout their life with a 3rd power-beyond line. later models included this from the factory.

anyway, I can narrow my question down to these two questions:

- can anyone confirm where this side-port (Green) line goes to?

- can anyone confirm that the red port goes to a 90deg elbow on the back of the tractor?

also, what are the consequences of guessing? I imagine either no control (fluid going strait to tank, or pressure side hooked up to tank side), triggering the relief valve on start-up, or weird control issues... but i'm not sure if one of those scenarios will damage something or myself

(Barrowed a pic from another thread)