Hi Everyone, I'm the new owner of a very rust GC2310 TLB. I bought it for a cheap $500 mostly just so I could use the backhoe arm and hydraulics to build a small tow behind backhoe. But if the tractor can be made to run without spending too much $$ I'd rather just use the platform as it was intended.

I'm documenting the process on my YouTube Channel, if you want to follow along, the latest is here

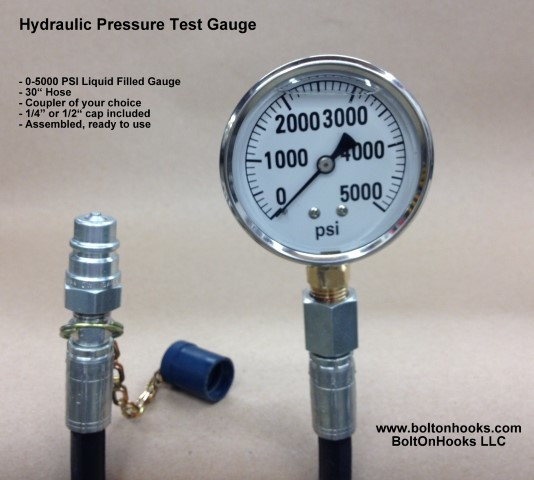

I'm at the next step in verifying operation of the tractor, checking out the hydraulics and transmission. My plan is to remove all the back sheet metal, the seat, maybe the fuel tank and expose the the backhoe/loader hydraulics. All the hydraulic hoses are trash, rusty balls of junk, so I want to close up the hydraulic/transmission system for testing. I also plan on draining and replacing the hydraulic fluid and the filter before testing the transmission.

My question is, can I simply plug the input/output fittings on the transmission that go for the loader and the backhoe or do I need a bypass pipe of some sort? It seems to me plugs would be ok, as that's what quick disconnects do when removed, but I'm not experienced working on hydraulic systems.

Any advice would be greatly appreciated.

John

I'm documenting the process on my YouTube Channel, if you want to follow along, the latest is here

I'm at the next step in verifying operation of the tractor, checking out the hydraulics and transmission. My plan is to remove all the back sheet metal, the seat, maybe the fuel tank and expose the the backhoe/loader hydraulics. All the hydraulic hoses are trash, rusty balls of junk, so I want to close up the hydraulic/transmission system for testing. I also plan on draining and replacing the hydraulic fluid and the filter before testing the transmission.

My question is, can I simply plug the input/output fittings on the transmission that go for the loader and the backhoe or do I need a bypass pipe of some sort? It seems to me plugs would be ok, as that's what quick disconnects do when removed, but I'm not experienced working on hydraulic systems.

Any advice would be greatly appreciated.

John