So this weekend I tackled the my gearbox crack with the quick and dirty JB Weld repair and so far so good. Hopefully the JB Weld will hold up to the heat, strain and vibration caused by regular use. Here are the pics, they were all taken with my iPhone so they are not the best quality.

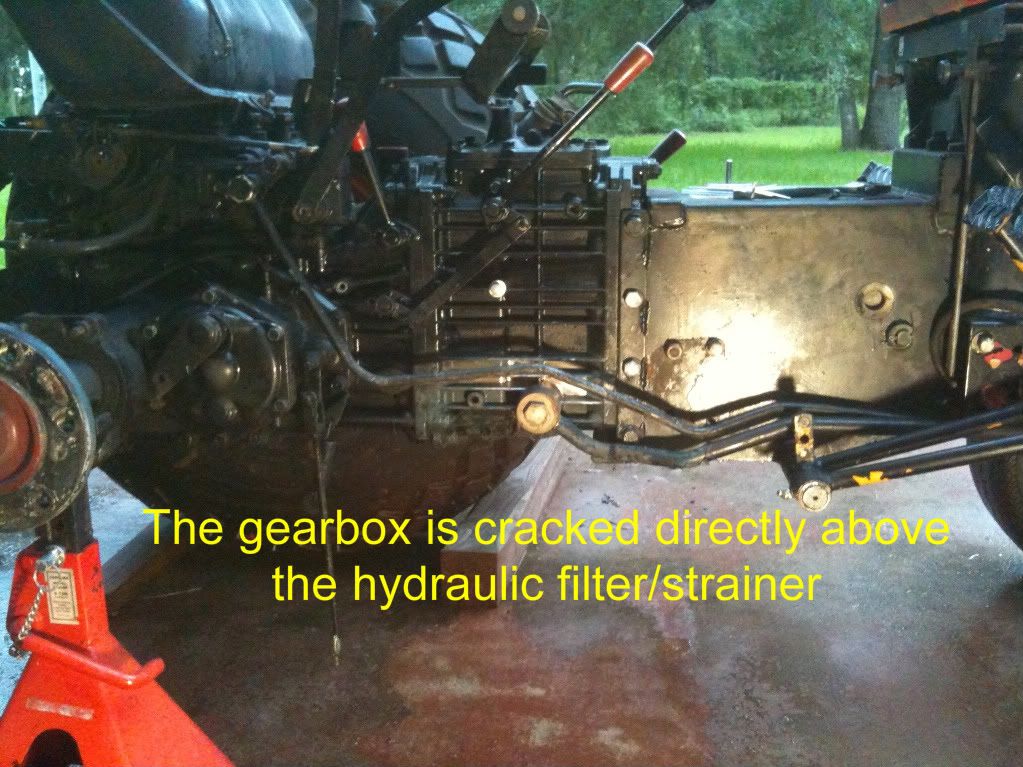

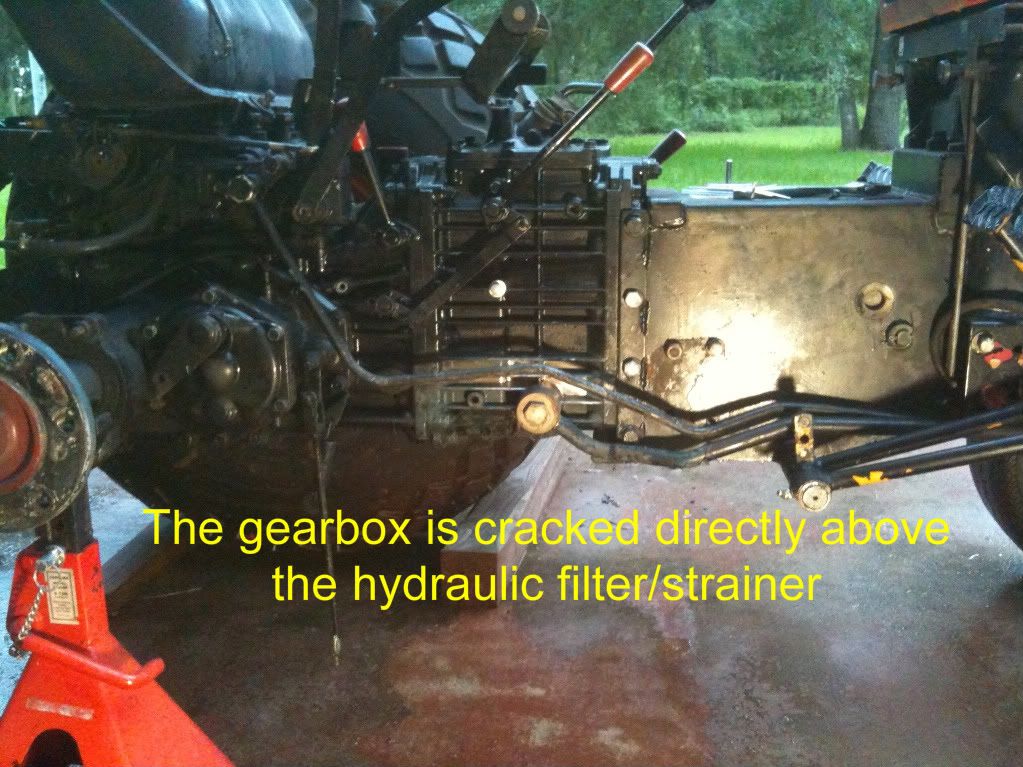

The crack was above the hydraulic strainer. I started by pressure washing the tractor, draining the hydraulic fluid, removing the tire, brake linkage, diff lock linkage, fuel line, and foot rest. I left the two hydraulic lines in place and worked around them, although they were in the way a little bit.

Here are the materials I used: Brakleen, Dremel tool with small brushes I got from Tractor Supply, Car-go Metal Tank Repair Kit, and JB Weld quick Steele.

To prepare the area I started by spraying it with Brakleen. This stuff is very powerful, it removes everything including paint. I followed up with my dremel tool with the wire brushes. This removed all the left over paint and exposed the bare metal and the crack.

Here is a picture of the crack:

close-ups:

I think the crack was caused by over tightening of the hydraulic strainer.

Next I used some sandpaper to scour the exposed metal and crack. Then sprayed it with Brakleen one final time and let it dry completely. I then mixed and applied the Car-Go Tank Repair putty, followed by the JB Weld. I found the JB Weld to be easier to mix and apply, and in retrospect I would have used it exclusively. I filled the entire area. This may be overkill, but I decided it would better for functionality and look.

I let the putty cure overnight and then sanded it down a little bit:

I then re-filled the gearcase with hydraulic fluid and checked for leaks.

So far so good, and if it stays that way I will prime and paint it.

The crack was above the hydraulic strainer. I started by pressure washing the tractor, draining the hydraulic fluid, removing the tire, brake linkage, diff lock linkage, fuel line, and foot rest. I left the two hydraulic lines in place and worked around them, although they were in the way a little bit.

Here are the materials I used: Brakleen, Dremel tool with small brushes I got from Tractor Supply, Car-go Metal Tank Repair Kit, and JB Weld quick Steele.

To prepare the area I started by spraying it with Brakleen. This stuff is very powerful, it removes everything including paint. I followed up with my dremel tool with the wire brushes. This removed all the left over paint and exposed the bare metal and the crack.

Here is a picture of the crack:

close-ups:

I think the crack was caused by over tightening of the hydraulic strainer.

Next I used some sandpaper to scour the exposed metal and crack. Then sprayed it with Brakleen one final time and let it dry completely. I then mixed and applied the Car-Go Tank Repair putty, followed by the JB Weld. I found the JB Weld to be easier to mix and apply, and in retrospect I would have used it exclusively. I filled the entire area. This may be overkill, but I decided it would better for functionality and look.

I let the putty cure overnight and then sanded it down a little bit:

I then re-filled the gearcase with hydraulic fluid and checked for leaks.

So far so good, and if it stays that way I will prime and paint it.