davel8257

Silver Member

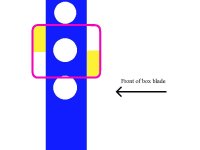

My shanks (knives) have holes (top pic) -- and the pins take all the force up and down. I'd like to see how CrazyAl's setup looks.

I was thinking of making wedges (maybe out of hard wood) and driving into the bottom of the tube against the shank. The wedge would create friction between the shank and bottom of the tube. The bottom of the tube would then bear some of the upward force. I'd probably have to top on top to loosen things up when I wanted to adjust them back up.

I started the hole drilling process -- by hand. I started with a 1/4" pilot hole through both sides. I had to use a hand drill -- no way to use my drill press for this job. Whew... quite a task. I've got other stuff going on, so the next hole increment may be a few days away.

I was thinking of making wedges (maybe out of hard wood) and driving into the bottom of the tube against the shank. The wedge would create friction between the shank and bottom of the tube. The bottom of the tube would then bear some of the upward force. I'd probably have to top on top to loosen things up when I wanted to adjust them back up.

I started the hole drilling process -- by hand. I started with a 1/4" pilot hole through both sides. I had to use a hand drill -- no way to use my drill press for this job. Whew... quite a task. I've got other stuff going on, so the next hole increment may be a few days away.