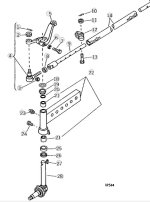

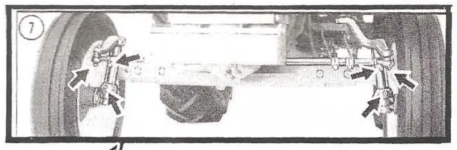

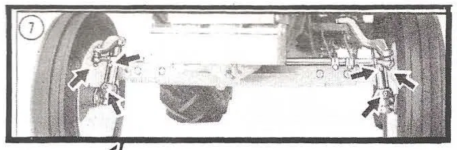

Have a 1981 JD 950 compact tractor that I am trying to service myself. Supposed to grease the steering spindles every 50 hours and according to JD there are two fittings on each spindle but I can only find one. Manual says to "remove the RELIEF PLUGS and apply several shots of grease to spindles." Here are some images:

I can see only one grease fitting and I'm not sure what the relief plugs are. Any help is appreciated.

I can see only one grease fitting and I'm not sure what the relief plugs are. Any help is appreciated.