You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help in Hydr. Motor with hydraulic clutch port.

- Thread starter polemidis

- Start date

- Views: 2218

More options

Who Replied?

/ Help in Hydr. Motor with hydraulic clutch port.

#11

oldnslo

Super Member

The sequence and check valve will work as long as the check vents to tank. That would require a motor spool if connected to the motor port.

WranglerX

Super Member

The real question is what is considered free wheeling,... How much energy (pounds pull) will it take to unspool (freewheel) the cable/winch drum...

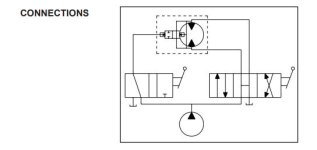

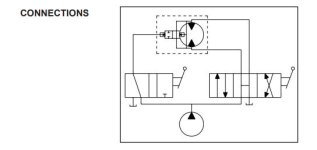

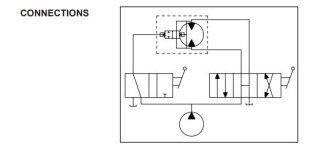

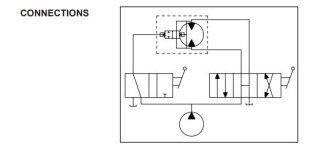

The valving is simple, apply pressure to clutch port motor is engaged, remove pressure from clutch port motor disengages, its all there in data sheet....... You are making valving more complicated then it needs to be... Single (one) valve to control clutch, single (one) valve to control motor rotation...

Dale

The valving is simple, apply pressure to clutch port motor is engaged, remove pressure from clutch port motor disengages, its all there in data sheet....... You are making valving more complicated then it needs to be... Single (one) valve to control clutch, single (one) valve to control motor rotation...

Dale

Last edited:

The real question is what is considered free wheeling,... How much energy (pounds pull) will it take to unspool (freewheel) the cable/winch drum...

The valving is simple, apply pressure to clutch port motor is engaged, remove pressure from clutch port motor disengages, its all there in data sheet....... You are making valving more complicated then it needs to be... Single (one) valve to control clutch, single (one) valve to control motor rotation...

View attachment 586943

Dale

You may be right. Simple is what I want to keep.

The real question is what is considered free wheeling,... How much energy (pounds pull) will it take to unspool (freewheel) the cable/winch drum...

The valving is simple, apply pressure to clutch port motor is engaged, remove pressure from clutch port motor disengages, its all there in data sheet....... You are making valving more complicated then it needs to be... Single (one) valve to control clutch, single (one) valve to control motor rotation...

View attachment 586943

Dale

You may be right. Simple is what I want to keep. But addind another parallel circuit adds a TEE, the valve, and a drain. But maybe it can get simpler with a tee in the hose on one work port. That way I do not need the extra valve or the drain. Just because I need only one direction on the motor.

Anyway, its not a big deal now, I believe I got how it works.

Thank you everybody!

muddstopper

Veteran Member

I think oldnslow is correct, without pressure to the clutch port, the motor should freewheel.Not sure how well just teeing into the work port is going to work. The port will not build any pressure until there is a load on the winch. In other words, if you pull off more cable than you need to pull your log, will the pressure build up enough to work the clutch with very little line load. No information as to how much pressure or flow is needed to engage the clutch. My next question would be do you intend to mount the winch drum directly to the motor. If so what dia drum would you be using and what would be the line speed. I am thinking 200rpms might be pretty quick with the drum directly mounted on or to the motor shaft. Use of gearing would slow the line speed, but would also make unspooling the winch cable a little harder.

My next question is why use hydraulics for the winch. It would seem to me a electric winch would be easier to setup and you woud have the option to use a remote to operate. That way you could be winching while your walking back to the machine after hooking up a log. Using a larger than needed electric winch will help keep battery drain down unlike using to small of atv type winch which woud overheat and kill a good battery. I will assume that since you are wanting to use a 20gpm motor as a winch, you have a large enough engine to keep a battery charged.

My next question is why use hydraulics for the winch. It would seem to me a electric winch would be easier to setup and you woud have the option to use a remote to operate. That way you could be winching while your walking back to the machine after hooking up a log. Using a larger than needed electric winch will help keep battery drain down unlike using to small of atv type winch which woud overheat and kill a good battery. I will assume that since you are wanting to use a 20gpm motor as a winch, you have a large enough engine to keep a battery charged.

Direct yes. 3" in diameter. 8.3ft/sec with no load, 2.6ft/sec when the pressure rises (I use a 2 stage log splitter pump) 22gpm up to 900psi, 7gpm up to 2700psiMy next question would be do you intend to mount the winch drum directly to the motor. If so what dia drum would you be using and what would be the line speed. I am thinking 200rpms might be pretty quick with the drum directly mounted on or to the motor shaft. Use of gearing would slow the line speed, but would also make unspooling the winch cable a little harder.

A simple 16hp gas engine. I do not think it will produce enough juice to keep the battery charged. The electric winch will empty it fast. Electric winch with remote would be nice, but I cannot keep up with the draw. I havent' done the math, but it feels like there is no way to keep up.My next question is why use hydraulics for the winch. It would seem to me a electric winch would be easier to setup and you woud have the option to use a remote to operate. That way you could be winching while your walking back to the machine after hooking up a log. Using a larger than needed electric winch will help keep battery drain down unlike using to small of atv type winch which woud overheat and kill a good battery. I will assume that since you are wanting to use a 20gpm motor as a winch, you have a large enough engine to keep a battery charged.

Yeah oldslo is right just a tee probably will not work.

Last edited:

farm boy00

Veteran Member

- Joined

- Jul 17, 2014

- Messages

- 1,296

- Location

- Howard City, MI

- Tractor

- John Deere M&MT, Case 1030 comfort king, Sears ST16, Craftsmen 6000, homemade articulation mini-loader

Because electric winches do not provide the duty cycle to do long pulls steadily without wrecking batteries and tractors usually do not put out enough amps through the alternator to recharge batteries between pulls (30-40 amps).I think oldnslow is correct, without pressure to the clutch port, the motor should freewheel.Not sure how well just teeing into the work port is going to work. The port will not build any pressure until there is a load on the winch. In other words, if you pull off more cable than you need to pull your log, will the pressure build up enough to work the clutch with very little line load. No information as to how much pressure or flow is needed to engage the clutch. My next question would be do you intend to mount the winch drum directly to the motor. If so what dia drum would you be using and what would be the line speed. I am thinking 200rpms might be pretty quick with the drum directly mounted on or to the motor shaft. Use of gearing would slow the line speed, but would also make unspooling the winch cable a little harder.

My next question is why use hydraulics for the winch. It would seem to me a electric winch would be easier to setup and you woud have the option to use a remote to operate. That way you could be winching while your walking back to the machine after hooking up a log. Using a larger than needed electric winch will help keep battery drain down unlike using to small of atv type winch which woud overheat and kill a good battery. I will assume that since you are wanting to use a 20gpm motor as a winch, you have a large enough engine to keep a battery charged.

When winching a vehicle, you usually do not winch for a very long time and the vehicles usually have a big alternator (100+amps).

WranglerX

Super Member

Most tractors do not have battery/alternator/generator capacities for sustained pulling.... Did a few pulls with my Jeep 10,000 lb winch recently and after about a minute (or less) winch sucked system voltage down to 8 volts and warning lights lit up like Christmas tree in dash.... Jeep has 100 Amp alternator and it was running at about 2000 rpm so full alternator out put and Jeep has large Odyssey AGM battery with 850 CCA and winch sucked it down pretty good....

But it did break a 5/16 1900lb proof chain...

Also makes me think when (if) 100 Amp alternator dies in Jeep I might replace ig with 200 amp for winch work...

Electric winches have their uses in recovery and such , but for sustained pulling (logging, really long pulls, moving stuff) think hydraulic or PTO is best solution...

Dale

But it did break a 5/16 1900lb proof chain...

Also makes me think when (if) 100 Amp alternator dies in Jeep I might replace ig with 200 amp for winch work...

Electric winches have their uses in recovery and such , but for sustained pulling (logging, really long pulls, moving stuff) think hydraulic or PTO is best solution...

Dale

I give it a second thought. In this diagram on their data sheet,

the clutch port does not really get pressurized in advance, as the oil follow the path of least resistance, which simply is towards the tank through the valve on the right.

So If I do the following connection I do not see why It will not work one direction.

On the reverse, the clutch drains to the tank through the valve.

I will try it, worse case scenario it will not work. Nothing will blow up here.

the clutch port does not really get pressurized in advance, as the oil follow the path of least resistance, which simply is towards the tank through the valve on the right.

So If I do the following connection I do not see why It will not work one direction.

On the reverse, the clutch drains to the tank through the valve.

I will try it, worse case scenario it will not work. Nothing will blow up here.