EddieWalker

Epic Contributor

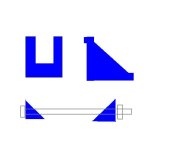

Here's my solution.

The pin extends out far enough that it should work as an anchor for an eye bolt. I bought a pair of them for $39.

Now I need to make an anchor on the attachment (grapple and then bucket) onto the QA.

My plan is to make a sort of U out of some 3/8's metal so that I can slide the threaded end of the eye bolt into it, and then tighten the nut.

This seems to be the simplist, strongest way that I can think of. Too many pieces and it loses strength and become dificult to take on and off. This should be easy to install and remove.

Thanks,

Eddie

The pin extends out far enough that it should work as an anchor for an eye bolt. I bought a pair of them for $39.

Now I need to make an anchor on the attachment (grapple and then bucket) onto the QA.

My plan is to make a sort of U out of some 3/8's metal so that I can slide the threaded end of the eye bolt into it, and then tighten the nut.

This seems to be the simplist, strongest way that I can think of. Too many pieces and it loses strength and become dificult to take on and off. This should be easy to install and remove.

Thanks,

Eddie