Ed of all trades

Elite Member

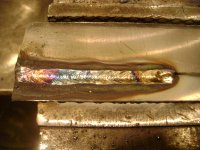

I picked up some "cheep" stainless 1x2 tubing for a fab job I want to do and got some E308/308L-16 3/32 rod. To say I am frustrated is an understatement. I have welded all my life and I can't get a good weld. Even with a wide zig zag the arc will stay on the side I started on and I get a weld on one side only. tilting the rod does not help, it is like the flux is keeping the arc from jumping to the other side. Any help will be appreciated. I was running at 70 amps, what the box recommended, and reversing polarity did not help.