hwatkins

Member

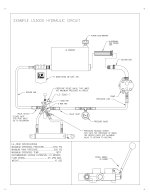

I built a three point hitch log splitter, the detent is supposed to operate the B Port. I have the B port hooked up to the lower part of the cylinder, which should cause it to retract, but instead it causes it to extend. The other issue is the valve is supposed to have a rapid extend feature, but when I try to engage that the ram sputters, like it can't decide if it should move up or down.

I've gone over the hookups but can't see an issue. I've attached some pictures to show the hookups. Any ideas on ways to troubleshoot?

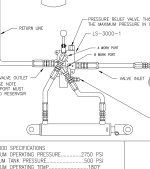

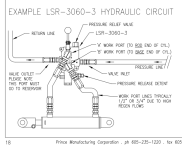

Prince Model LS3060 Rapid Extend Log Splitter Valve

Prince PTO HC-PTO-2AC Pump

I've gone over the hookups but can't see an issue. I've attached some pictures to show the hookups. Any ideas on ways to troubleshoot?

Prince Model LS3060 Rapid Extend Log Splitter Valve

Prince PTO HC-PTO-2AC Pump