Scott65

Silver Member

Hey guys, kinda in a pinch here. I'm hoping someone can shed some light. I've pre-ordered all of my parts to make a grapple on the front of my Kubota L3301. All is rigged up but when I push the valve in either direction, it just locks up the cylinder and won't operate the grapple in either direction. The power beyond is all hooked up correctly because I have all other functions (loader and 3 point). And the pump isn't laboring when all is in neutral. It bogs down when I attempt to operate the valve, just like when the loader is maxed out, and fluid comes through the "return to tank" line as it should when over-pressurized.

This may be simple: I contacted Baileys several months ago and purchased the valve that they suggested. I never thought twice until right now. I just looked it back up on their website and instead of open center, its labeled as tandem center. Research shows that when in neutral, it holds pressure in the 2 work lines. But I don't find anything about what it does when you activate the valve. Is it that its applying pressure to one work port, but dead-heading it in the other, therefor blocking the fluid return path for the cylinder to operate?

And if this is the problem, is there a way to fix it without replacing the valve? My thought was to try drilling a hole in the power beyond plug to allow the "tank" pressure to bleed into the power beyond port, since loosening that was the only way to relieve the pressure in the ram. I'm sure this isn't the correct way, but will it work? I'm stuck, I need this thing working, and I don't have any other sorts of fittings to replumb it at the moment.

In case anyone needs to know, its a Chief Directional control valve, 4 way, 3 position.

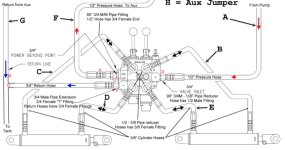

It has 2 work ports, A and B. The inlet port, and tank port, labeled T. Then I was instructed to pull the plug from the N port, install it in the T port, and put the optional Power Beyond adapter back in the N port, and hook my "out" line to that, going to the block underneath the tractor and back to the 3-point

This may be simple: I contacted Baileys several months ago and purchased the valve that they suggested. I never thought twice until right now. I just looked it back up on their website and instead of open center, its labeled as tandem center. Research shows that when in neutral, it holds pressure in the 2 work lines. But I don't find anything about what it does when you activate the valve. Is it that its applying pressure to one work port, but dead-heading it in the other, therefor blocking the fluid return path for the cylinder to operate?

And if this is the problem, is there a way to fix it without replacing the valve? My thought was to try drilling a hole in the power beyond plug to allow the "tank" pressure to bleed into the power beyond port, since loosening that was the only way to relieve the pressure in the ram. I'm sure this isn't the correct way, but will it work? I'm stuck, I need this thing working, and I don't have any other sorts of fittings to replumb it at the moment.

In case anyone needs to know, its a Chief Directional control valve, 4 way, 3 position.

It has 2 work ports, A and B. The inlet port, and tank port, labeled T. Then I was instructed to pull the plug from the N port, install it in the T port, and put the optional Power Beyond adapter back in the N port, and hook my "out" line to that, going to the block underneath the tractor and back to the 3-point