Okay. I thought I'd do a few drawing to show how this thing is currently plumbed. Also throwing in a couple of revisions.

I know I'll need to acquire a few more pieces and parts so drawing it out helps in detailing what I need. I love living in "fly-over" country but getting parts can be a challenge. Sometimes I feel like that guy in the movie "O'Brother" whose told that it will take two weeks to get a new transmission belt for his Model T - "This place is a gol-dang geographic oddity, two weeks from anywhere!".

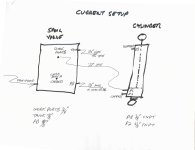

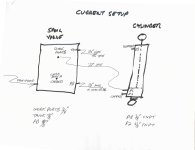

Here's a simplified picture of the current plumbing. It works, kindof. The weight goes up, somewhat slowly. The weight comes down WAY TOO SLOW:

Several contributors have suggested that the problem is that the hydraulic fluid flow is being unduly restricted. The spool valve has a 3/4" work port. I'm currently reducing that down to 1/2" hose, then finally the port on the cylinder is only 3/8".

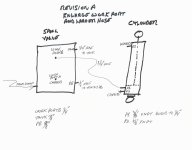

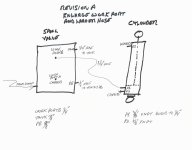

So let's first look at enlarging the cylinder work port to at least 3/4" and then increasing the working hose to that size:

Pros:

o I can control up/down with the single spool valve

o Only need to change one hose

Cons:

o I'm constrained by the internal porting of the spool valve, whatever that may be

o May introduce excessive heat to the spool valve

I noticed that the cylinder actually has two 3/8" work ports on the non-rod end. Here's a scenario where we enlarge that second work port to 3/4" and add a 3/4" ball valve, leaving the plumbing for the first work port intact:

Pros:

o The first work port plumbing isn't being changed, so the "up" speed will remain predicable

o The ball valve allows for a quick dump of the hydraulic fluid back to tank. In theory this should make the weight drop twice as fast

o Bypassing the spool valve for the down stroke should extend the life of the valve as well as avoiding any internal restrictions

o The spool valve can still be used for a slow controlled up and down. This would is useful for positioning and locking the pounder for road travel

Cons:

o Driving posts requires the coordination of manipulation too separate valves

o Cost of ball valve and extra hoses

And then finally an option that again involves increasing the work port and hoses to 3/4" but adding a tee inline:

Pros:

o The first work port plumbing IS being changed, so the "up" speed MIGHT be faster

o The ball valve allows for a quick dump of the hydraulic fluid back to tank. In theory this should make the weight drop twice as fast

o Bypassing the spool valve for the down stroke should extend the life of the valve as well as avoiding any internal restrictions

o The spool valve can still be used for a slow controlled up and down. This would be useful for positioning and locking the pounder for road travel

Cons:

o The first work port plumbing IS being changed, so the "up" speed MIGHT be slower

o Driving posts requires the coordination of manipulation too separate valves

o Cost of ball valve, tee and extra hoses

I have a new found respect for the folks that design these systems. There's a lot to think about.

Thoughts on the revisions?