oh, so you just welded this coupling over the cylinder?? I would never thought of that! My problem is I do not have any metal lathe and if I am about to go to a machine shop it will cost me the same as buying an more expensive trunnion cylinder in the first place. Anyway I will keep that option in my mind.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Homemade Backhoe for LS Tractor (XG3140)

- Thread starter polemidis

- Start date

- Views: 8708

More options

Who Replied?

/ Homemade Backhoe for LS Tractor (XG3140)

#21

TMGT

Elite Member

I dont have a picture on my phone but I was able to make a trunion without a lathe so it's still doable. Not as nice as BFreaky's but it works.

TMGT

Elite Member

Ok good. For some reason I had never thought that I could weld on the cylinder.

So, I am doing the geometry circles and stuff. I really do not see any huge difference with the trunnion, on the force or on the angle spread. In my mind yes, it should work better, but in paper it does not. I can post the diagrams to support what I am saying if you want. One thing i see different is the swing angle that has the max force. With the trunnion is closer to the ends of the swing arc, with the regular cylinder mount is towards the center.

If the industry uses trunnion is should be for a reason, but I have not figured out it yet Maybe because the mounts are more convenient located?

Maybe because the mounts are more convenient located?

So, I am doing the geometry circles and stuff. I really do not see any huge difference with the trunnion, on the force or on the angle spread. In my mind yes, it should work better, but in paper it does not. I can post the diagrams to support what I am saying if you want. One thing i see different is the swing angle that has the max force. With the trunnion is closer to the ends of the swing arc, with the regular cylinder mount is towards the center.

If the industry uses trunnion is should be for a reason, but I have not figured out it yet

ptsg

Super Member

Trunnion mounts usually takes less space and by moving the pivot point forward, it will allow the backhoe to rotate a full 180 degree from one side to another without the cylinder overpass the main pivot point which would cause problems.

Trunnion mounts usually takes less space and by moving the pivot point forward, it will allow the backhoe to rotate a full 180 degree from one side to another without the cylinder overpass the main pivot point which would cause problems.

That is what I suspected in the beginning, but I cannot see that in the actual diagram. I will upload them later tonight, to see what I mean. Maybe I am missing something that you can see guys.

TMGT

Elite Member

How many degrees of swing are you going for? If you're going for a bit less then 180* then yes you can get by without trunion mounts. Otherwise you will run into overcenter issues or stall problems because the cylinders start fighting each other.

One thing I can say from experience, you'll want as much swing as possible, a lot of times I wish I had more then 180!

One thing I can say from experience, you'll want as much swing as possible, a lot of times I wish I had more then 180!

texasranger556

Platinum Member

SC has several options in the sub $100 range

Surplus Center

Another option is a dual ended cylinder and chain like Woods used to use.

https://www.tractorbynet.com/forums...6500-backhoe-dolly-kubota-20130421_175138-jpg

And a general note, most backhoes I've seen run the swing cylinders between the upper and lower pivots. It balances the forces better and leaves more room for your feet.

Surplus Center

Another option is a dual ended cylinder and chain like Woods used to use.

https://www.tractorbynet.com/forums...6500-backhoe-dolly-kubota-20130421_175138-jpg

And a general note, most backhoes I've seen run the swing cylinders between the upper and lower pivots. It balances the forces better and leaves more room for your feet.

Last edited:

Sorry guys, somehow my reply didnt get through.

Texasranger, the cylinders have to go above the upper pivot, as Bfreaky's one. The reason is that the hydraulic tank is in the way. I understand it should go somewhere between the upper and lower, but really, there is no other place. I dont worry much though because the swing cylinders are only moving the backhoe, they are not applying lots of force. I actually think to add an extra relief valve (a crossover valve actually )on their circuit in order to limit the pressure so to avoid possible damage on BH in case of some collision.

Bfreaky! what is that monster?? hahaha! I would actually want 360, and build an excavator but thats another project for another day I keep finding cheap 150hp diesel engines and i get temped but no money-no honey

I keep finding cheap 150hp diesel engines and i get temped but no money-no honey

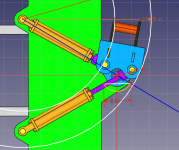

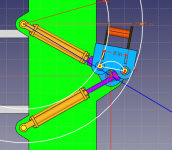

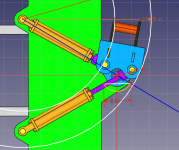

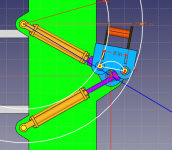

TMGT, I will go with just below 180. I could not find how the trunnion will help. This is my sketch for regular cheap cylinders. The blue line is 180 line for the left (upper in the sketch) swing cylinder rod pivot. Bfreaky explained it to me, I may hadn't thought it on my own, that the trick that make 180 possible is that the cylinder rod can go over the central pivot point, because the cylinders are on top of the assembly (and not between the upper and lower pivots)

The blue mount in theory can move up to <180ー , you can see in one picture that the cylinder rod (purple) has almost 0.5" more to retract.

So I will just put my bumper end stops 1ー below 180 and I will just adjust them to make sure it will never go above 180 in the actual practice.

In the diagram, the big arcs are the cylinder limits. I regular 3"x8" cylinder with 20.25" retractred length, and 28.25 extended length. (I should use 3x6" but surplus didnt had them cheap, but it does not really matter)

Texasranger, the cylinders have to go above the upper pivot, as Bfreaky's one. The reason is that the hydraulic tank is in the way. I understand it should go somewhere between the upper and lower, but really, there is no other place. I dont worry much though because the swing cylinders are only moving the backhoe, they are not applying lots of force. I actually think to add an extra relief valve (a crossover valve actually )on their circuit in order to limit the pressure so to avoid possible damage on BH in case of some collision.

Bfreaky! what is that monster?? hahaha! I would actually want 360, and build an excavator but thats another project for another day

TMGT, I will go with just below 180. I could not find how the trunnion will help. This is my sketch for regular cheap cylinders. The blue line is 180 line for the left (upper in the sketch) swing cylinder rod pivot. Bfreaky explained it to me, I may hadn't thought it on my own, that the trick that make 180 possible is that the cylinder rod can go over the central pivot point, because the cylinders are on top of the assembly (and not between the upper and lower pivots)

The blue mount in theory can move up to <180ー , you can see in one picture that the cylinder rod (purple) has almost 0.5" more to retract.

So I will just put my bumper end stops 1ー below 180 and I will just adjust them to make sure it will never go above 180 in the actual practice.

In the diagram, the big arcs are the cylinder limits. I regular 3"x8" cylinder with 20.25" retractred length, and 28.25 extended length. (I should use 3x6" but surplus didnt had them cheap, but it does not really matter)