Fallon

Super Member

Thanks!

Should I start a new thread?

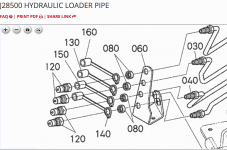

I just noticed a leak on the floor. I thought it was just from taking the hoses on and off. I wiped everything down best i could and revved it up to 2000 rpm's. I can see the blue male end leaking from the center pin piece. Is this something I can order and simply screw on and off myself or should I have the shop do it? It's still under warranty. I wonder if it has anything to do with the hydraulic cylinder breaking a few days ago, when I turned the blade to the left and it popped. Is left blue?

Please advise.

If those QDs were connected when things popped those sealing surfaces would be not touching at all. It could be a result of the repairs if you got any pipe tape, dope or other grit in there. It would prevent the poppet in the QD from sealing properly if it got lodged in the wrong spot. As likely to be a cheap or defective QD though. They are $30 or so to replace, but your dealer should take care of things under warranty.

It's not as easy as just unscrewing. You have to find 1, maybe 2 wrenches, possibly some pipe dope. Then there is the whole grunting while using the wrenches. Were talking at least 5 minutes of work, more if you properly apply beer at appropriate intervals. It might even be half as hard as replacing the hose & use almost the same techniques.

When I had a hose weep a little bit I sent my dealer a photo. Picked up the new hose from him later & installed it myself. Was far easier than hauling the machine in for them to do it. Had to later take the defective hose back to complete the warranty stuff, which was annoying, but not to bad.

Revving the engine up should have no effect on that QD leaking, unless the control valve is leaking a LOT. Maybe the extra vibrations or something, but there should be no real pressure on that QD unless you as actuate the valve.