wi4x4man

New member

Hi,

I have been looking for quite some time, but I cannot seem to find out how the hydraulic system works on my 4230.

I recently purchased it to replace the ol' 4020 that I have used for years. Nothing wrong with the 4020, except I do a lot of work in the winter and I am just tired of freezing my butt off. The 4020 had a 148 loader on it, and I pulled it to put it onto the 4320 so I needed a power beyond kit.

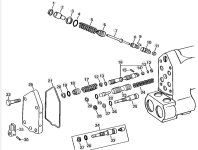

I installed the power beyond kit behind the right SCV but I got to thinking... How in blazes does the hydraulic system actually work? There are no valves in the power beyond. And given the fact that I have an open center hydraulic valve on that is cable actuated (pretty sure it is open center anyways) how is the system going to develop pressure to the loader valve? Are the SVC's closed center, or are they open center systems? My guess is that they must be closed center?

Does anyone have a schematic out there that shows how the hydraulic systems work on these older machines. Deere has used that type of hydraulic system for years and years, and I thought I would be able to find something. But I can't.

Any help would be greatly appreciated!

I have been looking for quite some time, but I cannot seem to find out how the hydraulic system works on my 4230.

I recently purchased it to replace the ol' 4020 that I have used for years. Nothing wrong with the 4020, except I do a lot of work in the winter and I am just tired of freezing my butt off. The 4020 had a 148 loader on it, and I pulled it to put it onto the 4320 so I needed a power beyond kit.

I installed the power beyond kit behind the right SCV but I got to thinking... How in blazes does the hydraulic system actually work? There are no valves in the power beyond. And given the fact that I have an open center hydraulic valve on that is cable actuated (pretty sure it is open center anyways) how is the system going to develop pressure to the loader valve? Are the SVC's closed center, or are they open center systems? My guess is that they must be closed center?

Does anyone have a schematic out there that shows how the hydraulic systems work on these older machines. Deere has used that type of hydraulic system for years and years, and I thought I would be able to find something. But I can't.

Any help would be greatly appreciated!