Wild Bill the 2nd

Gold Member

I am working on a firewood processor and am looking to build a hydraulic tank. I had some questions, in particular about baffle design.

Note: The processor will have a 17 GPM saw pump, 6.5 GPM pump for misc cylinders, and a 28/7 GPM 2 stage pump for the splitter. That is up to 51.5 GPM.

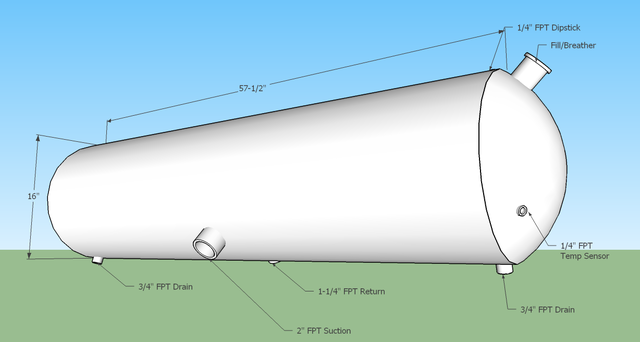

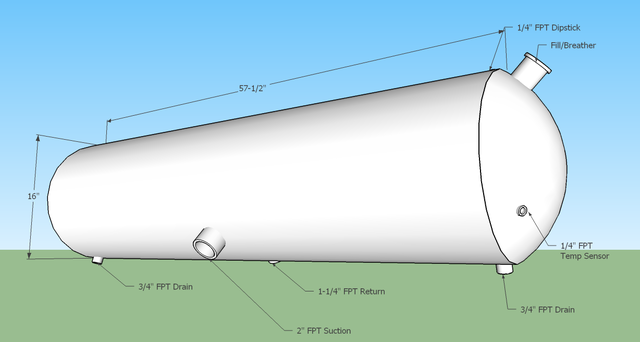

Here is my current design. Work has some 16" OD dished lids that are scrap due to the metallurgical properties not being correct. At 16" Dia. you get 1.15 gal per inch of length. I have roughly decided on a 50 gallon tank which comes to about 57.5" in length. (I am not including the amount of fluid in the dished ends in my calculation, it is extra capacity) I was thinking we'd fill it with 40 to 45 gallons. I have a 2" suction port and a 1.25" return port, two 3/4" drains, and two 1/4" fittings for a temp sensor and a dipstick.

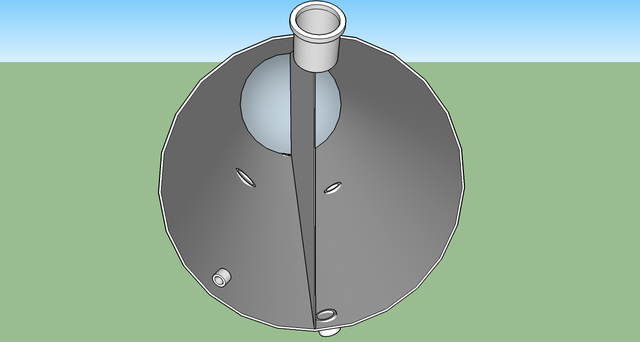

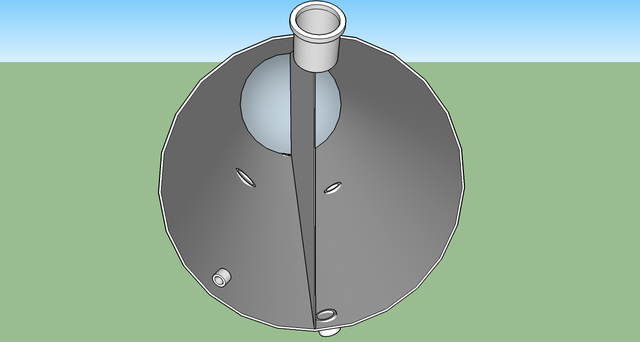

This pic shows the dished end removed. My plan for the baffle was to have it run top to bottom the full length of the rolled tank. Return comes in on one side of the baffle and the suction is on the other. The fluid will be forced to travel to the dished ends to get back around to the suction side.

I think the tank will have a lot of surface area for the volume of fluid. I'm not sure if that will allow us to get away without a hydraulic fluid cooler due to the shear GPM the pumps will be putting out.

Opinions on anything? Baffle? Port sizes/qty? Tank volume? Think it will work? Am I missing anything?

Note: The processor will have a 17 GPM saw pump, 6.5 GPM pump for misc cylinders, and a 28/7 GPM 2 stage pump for the splitter. That is up to 51.5 GPM.

Here is my current design. Work has some 16" OD dished lids that are scrap due to the metallurgical properties not being correct. At 16" Dia. you get 1.15 gal per inch of length. I have roughly decided on a 50 gallon tank which comes to about 57.5" in length. (I am not including the amount of fluid in the dished ends in my calculation, it is extra capacity) I was thinking we'd fill it with 40 to 45 gallons. I have a 2" suction port and a 1.25" return port, two 3/4" drains, and two 1/4" fittings for a temp sensor and a dipstick.

This pic shows the dished end removed. My plan for the baffle was to have it run top to bottom the full length of the rolled tank. Return comes in on one side of the baffle and the suction is on the other. The fluid will be forced to travel to the dished ends to get back around to the suction side.

I think the tank will have a lot of surface area for the volume of fluid. I'm not sure if that will allow us to get away without a hydraulic fluid cooler due to the shear GPM the pumps will be putting out.

Opinions on anything? Baffle? Port sizes/qty? Tank volume? Think it will work? Am I missing anything?