You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hydraulic Top Link for a 2320

- Thread starter katt68

- Start date

- Views: 9025

More options

Who Replied?

/ Hydraulic Top Link for a 2320

#1

beenthere

Super Star Member

- Joined

- Aug 16, 2001

- Messages

- 18,616

- Location

- Southern Wisconsin, USA

- Tractor

- JD_4x2_Gator, JD_4300, JD_425, JD_455 AWS, added JD_455, JD_110, JD_X485(sold)

Searching on this forum gets

http://www.tractorbynet.com/forums/hydraulics/186690-installing-2-spool-selective-control.html

http://www.tractorbynet.com/forums/hydraulics/186690-installing-2-spool-selective-control.html

MtnViewRanch

Elite Member, Advertiser

- Joined

- Mar 19, 2005

- Messages

- 10,697

- Tractor

- Mahindra 7520, Mahindra 3215HST, Case 580 extendahoe, Case 310 dozer, Parsons trencher, Cat D6,

A complete Top Link kit for your 2320 that includes a cat 1 top link with a working length of 17 1/2"- 25 1/2", a hose kit with quick connect ends and a hydraulic flow restrictor would run you $240 + shipping. You might need to get the control valve, or do you already have that?

A complete Top Link kit for your 2320 that includes a cat 1 top link with a working length of 17 1/2"- 25 1/2", a hose kit with quick connect ends and a hydraulic flow restrictor would run you $240 + shipping. You might need to get the control valve, or do you already have that?

areyou talking about a divertor valve?

MtnViewRanch

Elite Member, Advertiser

- Joined

- Mar 19, 2005

- Messages

- 10,697

- Tractor

- Mahindra 7520, Mahindra 3215HST, Case 580 extendahoe, Case 310 dozer, Parsons trencher, Cat D6,

areyou talking about a divertor valve?

I'm not indicating any type of valve. Just that if you did not already have any rear remotes you will need some type of control valve. If you only want the one rear remote, then a diverter valve may be your easiest option.

greg_g

Super Member

- Joined

- Dec 18, 2003

- Messages

- 6,126

- Location

- Western Kentucky

- Tractor

- JD3720 Cab, 300X loader with 4-in-1 bucket

Depends upon how your tractor is configured. I have two sets of control valves connected to my joy stick. They're physically located beneath and forward of the right cab door. I assume they're in the same location on the open station. One controls the loader lift and curl, the other controls the two sets of rear remotes. My HTL is plugged into one of the two rear sets. I have an illuminated electric switch on the right console that determines which is connected to the joystick. When I want to operate the loader, the switch is in position 1. When I want to operate the HTL, I have to move the switch to position 2areyou talking about a divertor valve?

But that's not the only way hydraulics on these CUTs can be configured. If yours is not like the above description, another owner will hopefully chime in.

//greg//

HayDR

Veteran Member, Approved Advertiser

has anyone made there one hydraulic toplink assembly for a 2320?

if so can you tell me what you did and installed?

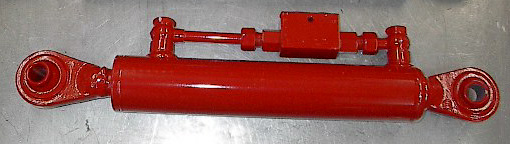

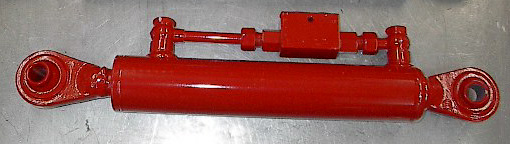

Complete with the anti-creep DPCV for $185. This has a hardened and chromed push rod with teflon rings. Forged CAT 1 ends. We have been selling these hydraulic top links for over 15 years and the first to market these on TBN.

shortthrow50

Banned

- Joined

- Jan 12, 2012

- Messages

- 930

- Tractor

- 2012 John Deere 3520 Deluxe Cab

Complete with the anti-creep DPCV for $185. This has a hardened and chromed push rod with teflon rings. Forged CAT 1 ends. We have been selling these hydraulic top links for over 15 years and the first to market these on TBN.

nice! how much is shipping to PA

HayDR

Veteran Member, Approved Advertiser

About $15nice! how much is shipping to PA

jenkinsph

Super Star Member

IMO, and I use a top link all the time I would get one without the check valves. Much easier to feather the adjustment without checks in the lines.

MtnViewRanch

Elite Member, Advertiser

- Joined

- Mar 19, 2005

- Messages

- 10,697

- Tractor

- Mahindra 7520, Mahindra 3215HST, Case 580 extendahoe, Case 310 dozer, Parsons trencher, Cat D6,

IMO, and I use a top link all the time I would get one without the check valves. Much easier to feather the adjustment without checks in the lines.

So Steve, now you use feathers when grading?

I tell people all the time that for grading, my Top and Tilt units are great. If they are farming, then maybe they should either stay with the OEM links or go with a link that has a DPOCV. There are situations where each type is better than the other. It all depends on what it is that a person is doing most of the time as to what type of link works out the best.

jenkinsph

Super Star Member

So Steve, now you use feathers when grading?Man you really do a fine touch when it comes down to the finishing touches. :thumbsup:

I tell people all the time that for grading, my Top and Tilt units are great. If they are farming, then maybe they should either stay with the OEM links or go with a link that has a DPOCV. There are situations where each type is better than the other. It all depends on what it is that a person is doing most of the time as to what type of link works out the best.

I find when changing directions with a boxblade or landplane grader you have to readjust the top link each time. That means frequent adjusting of the length of the top link.

For other jobs such as rototilling or brushhogging the check valves would be fine since these adjustments aren't need except for the initial setup and trim.

I guess I haven't realy noticed much cylinder creep with my setup so far, if the valves leak fluid past the spools I would fix it.

hanson1999

Gold Member

IMO, and I use a top link all the time I would get one without the check valves. Much easier to feather the adjustment without checks in the lines.

i agree. and i like the float function for mowers and other odd uses time to time.

MtnViewRanch

Elite Member, Advertiser

- Joined

- Mar 19, 2005

- Messages

- 10,697

- Tractor

- Mahindra 7520, Mahindra 3215HST, Case 580 extendahoe, Case 310 dozer, Parsons trencher, Cat D6,

I find when changing directions with a boxblade or landplane grader you have to readjust the top link each time. That means frequent adjusting of the length of the top link.

For other jobs such as rototilling or brushhogging the check valves would be fine since these adjustments aren't need except for the initial setup and trim.

I guess I haven't realy noticed much cylinder creep with my setup so far, if the valves leak fluid past the spools I would fix it.[/quote]

This is my situation exactly. I have actually tested mine a couple of times just so that I would know just how much my cylinders drift. Having the 3pt raised with a 1000lb load on it my side link falls pretty much right at 5/32" in one hour. WOW, I guess I should really have a DPOCV and forego all the advantages of not having a check valve on the cylinder.The top link extended about 1/16". Man that is just terrible, and unacceptable........ in some peoples eyes I guess. In the real world it is just fine and affects nothing, when it comes to grading anyway.

Just my opinion, others do vary.