SmallChange

Platinum Member

- Joined

- Apr 19, 2019

- Messages

- 763

- Tractor

- New Holland WM25 with 200LC front end loader, filled R4 tires 43X16.00-20 and 25X8.50-14 (had a Kubota B6200D with dozer and R1 tires)

I have a pole barn with roof trusses and want to attach an I beam up to the bottoms of the trusses to run my hoist and trolley across the trusses (that is, I beam perpendicular to trusses and parallel with roof ridge). The purpose is to make it easy to lift and move 3 point and skidder mount implements, which weigh less than half a ton, with the 1 ton chain hoist. My floor is uneven and tilted, and wheeling them around would be tough. I'm pretty sure this weight spread over multiple trusses will be OK; after all, four big men standing on the roof shouldn't make it collapse. Also, both ends of my I beam will be anchored to stud walls.

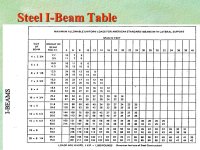

But how big an I beam to use? I'm thinking one of these:

S 4 x 9.5 lb (4.00" x .326" x 2.796")

S 5 x 10 lb (5.00" x .214" x 3.004")

S 6 x 12.5 lb (6.00" x .232" x 3.332")

These are all A36/A572-50 Standard Steel I Beam, and the dimensions are height by center web thickness by total width across flanges. My hoist manual says it will fit all these.

With the beam anchored to each truss, or more likely to a heavy board such as a joist laid the strong way across the trusses, it's not like it has to support the load at its center when itself supported only at the ends. It's got distributed support. My feeling is that even the 4" one would be more than strong enough.

What do you think?

Thanks!

But how big an I beam to use? I'm thinking one of these:

S 4 x 9.5 lb (4.00" x .326" x 2.796")

S 5 x 10 lb (5.00" x .214" x 3.004")

S 6 x 12.5 lb (6.00" x .232" x 3.332")

These are all A36/A572-50 Standard Steel I Beam, and the dimensions are height by center web thickness by total width across flanges. My hoist manual says it will fit all these.

With the beam anchored to each truss, or more likely to a heavy board such as a joist laid the strong way across the trusses, it's not like it has to support the load at its center when itself supported only at the ends. It's got distributed support. My feeling is that even the 4" one would be more than strong enough.

What do you think?

Thanks!