yankeerider

Platinum Member

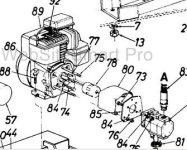

Well, I finally convinced my wife that there was no reason for her to fear the power of my 17 year old Duerr/MTD 5 hp/20 ton logsplitter. I bought this thing new, and have no idea how many hours it actually has on it. Anyway, about an hour into her splitting session (I was working nearby) I heard the engine start to labor and walked over to see what she was splitting that was so tough. Before I got to her, the engine had stalled. It has never done this in all the time I've owned it, so I knew something was up.

I grabbed the pull cord and, sure enough, the engine just didn't want to rotate freely. I began troubleshooting by uncoupling the hydraulic pump from the engine. That confirmed my suspicions that the engine was fine, but the pump was reluctant to rotate.

The next thing I noticed was that the key for the pump half of the lovejoy coupling had rotated almost out of the keyway. The coupling half is too far onto the pump shaft and the back of the coupling is in contact with the pump housing. So far, I have been unsuccessful in removing the coupling half from the pump input shaft, but in attempting to free it the pump has freed up. Attempts to move the coupling on the shaft seem to only be using end play of the shaft itself. I have a new pump on its way from Northern Tool (looks like a more exact fit than Surplus Center's offerings, with a 3/4 inlet), and will likely be replacing the coupling too- or at least the pump half and spider. Internal inspections suggest no internal damage or metallic contamination-good news for the other hydraulic components.

It will be put back together with special attention to the coupling installation. Question is, how does this type of coupling transmit enough thrust load into pump coupler/shaft to produce this much damage? (I haven't carefully inspected the engine half yet.) For now, I'm going on the assumption that the unit was improperly assembled when new, and it has taken all these years for the damage to progress to where it caused failure.

I grabbed the pull cord and, sure enough, the engine just didn't want to rotate freely. I began troubleshooting by uncoupling the hydraulic pump from the engine. That confirmed my suspicions that the engine was fine, but the pump was reluctant to rotate.

The next thing I noticed was that the key for the pump half of the lovejoy coupling had rotated almost out of the keyway. The coupling half is too far onto the pump shaft and the back of the coupling is in contact with the pump housing. So far, I have been unsuccessful in removing the coupling half from the pump input shaft, but in attempting to free it the pump has freed up. Attempts to move the coupling on the shaft seem to only be using end play of the shaft itself. I have a new pump on its way from Northern Tool (looks like a more exact fit than Surplus Center's offerings, with a 3/4 inlet), and will likely be replacing the coupling too- or at least the pump half and spider. Internal inspections suggest no internal damage or metallic contamination-good news for the other hydraulic components.

It will be put back together with special attention to the coupling installation. Question is, how does this type of coupling transmit enough thrust load into pump coupler/shaft to produce this much damage? (I haven't carefully inspected the engine half yet.) For now, I'm going on the assumption that the unit was improperly assembled when new, and it has taken all these years for the damage to progress to where it caused failure.