The Edwards really doesn't look too bad to me. The guys across the street have a 100 or so ton Edwards that looks far worse, but it's mostly just dirt and such from lack of use in the last few years (blame the economy). They seem to like it just fine. Looks like he might have several punch sets and some optional attachments to go with it. As Paul noted, those add up fast. I just bought a 1/2" square punch and die set. It cost about $120. I don't know the new price of the Edwards, so I don't really have a feel for the price. I noticed that it uses single phase power. That usually costs extra. Most iron workers are designed for constant use, so a small shop would probably never wear out the mechanicals.

I've used the Scotchman and Uni Hydro. We have a Piranha P-50 that I really like. It's faster than most other brands as it has a 10 hp motor instead of the 5 hp that most have. I really like the urethane hold downs and strippers. They save lots of time since they don't need much if any adjustment for different materials. It's also nice that the work height of all the stations except the angle shear, are the same height. That lets you use the same feed table or support for shearing. punching, notching, etc. The built in coper/notcher is really handy. I don't believe it's available in single phase though. Used ones show up at reasonable prices occasionally. If you don't have 3 phase power you'd need a 20 hp rotary converter to run it. I confess, ours looks pretty bad too. It's in great mechanical shape, but we have cutting, welding and grinding dust in that area of the shop. Seems like it attracts it all.

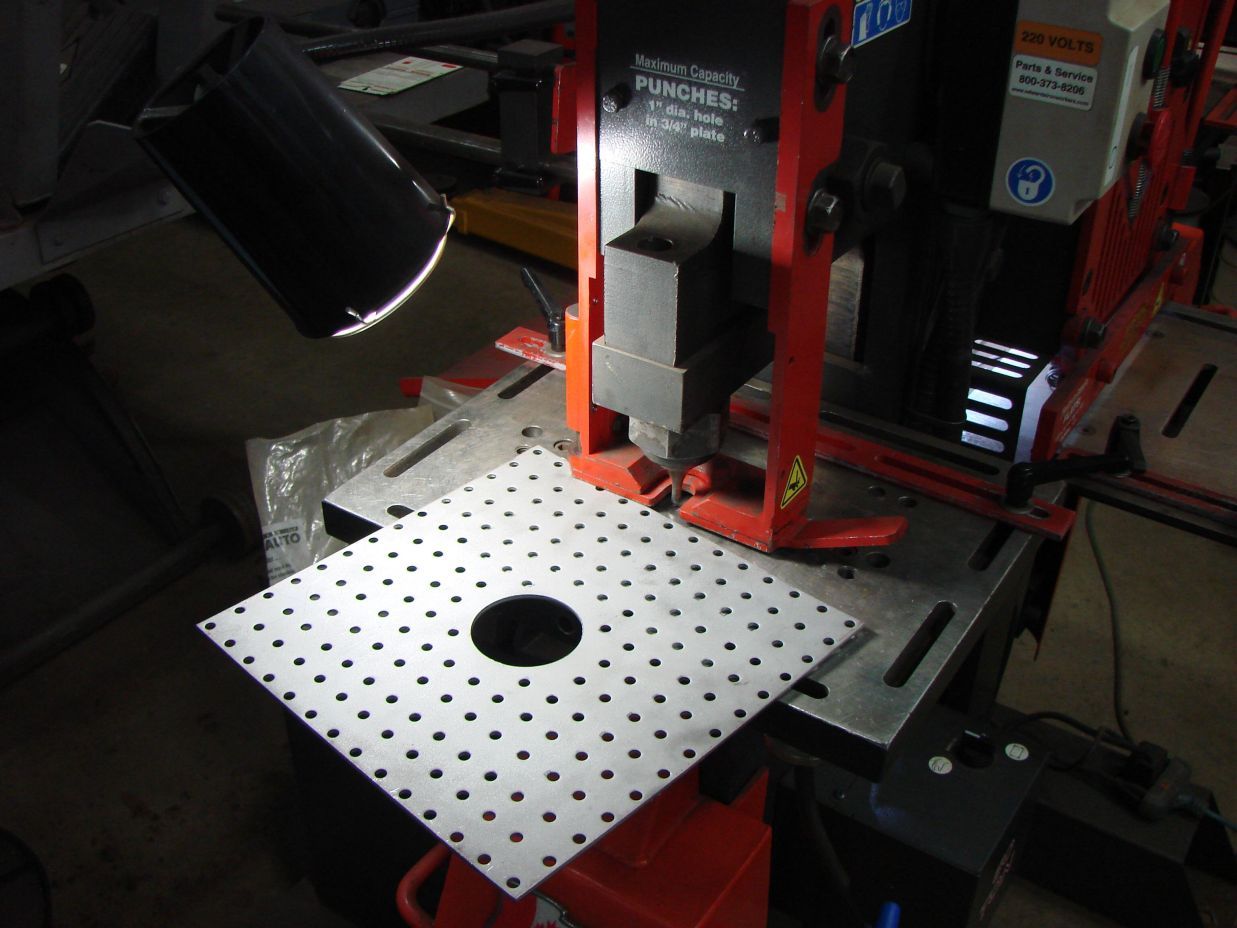

Paul keeps his machine immaculately clean. Don't expect to find a used machine that looks like that.

You should check shear knives and such. Replacements are in the $300-$500 range. Some blades have multiple edges and can be turned 4 times.