Tim Berframe

Bronze Member

About 2 years ago I put in a new E320 pump in my 2006 354. Worked great - big difference.

Last fall, I put my backhoe on for the first time in a couple of years. Tried pushing a 2'X2'X1' concrete block away from the tractor with the dipper motion. Instant shower of oil all over everything as the pump split.

Just fixing it now. I will put a pressure relief bypass in with the 2nd new pump. I have some questions for anybody who knows hydraulics:

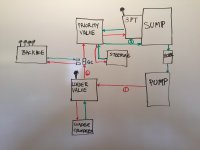

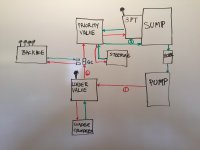

The first image shows how it is plumbed. The original PTO backhoe pump never worked from day 1. I plumb it into return line on the loader.

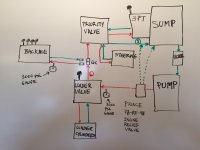

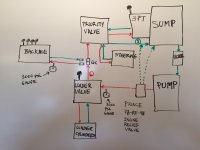

Image 2 shows the proposed alteration. I will put a Prince VA RV-4-H or a Princess Auto 8688947 Relief valve on pressure line # 1. Ill put gauges in by using a 'T' fitting at two locations so I can keep an eye on how hard I am pushing things in the future.

Questions:

What pressure should I set to?

Can I 'T' into the sump return line #3? If I do, do I need a one-way valve upstream of the 'T' on line #3? (This is a hard line)

Should I drill and tap a new hole into the sump to run the bypass hose into? Should the oil return below the liquid level in the sump?

Do you see any flaws in my plan? Will this fix, as proposed, avoid the same issue when I go out next weekend to finish moving those heavy concrete blocks?

(I am learning hydraulics slowly by fixing this machine. It seems to my logic that this machine is plumbed wrong to begin with. Shouldn't the pressure line off the pump go to the proportioning valve first so as to always give the steering first chance at oil flow. Also the pressure relief is in there? It has a Koyker loader so I guess it came from factory hard line plumbed without consideration of a loader circuit. They plumbed it this way so they did't have to replace hard lines?)

Thanks for any help,

Tim

Last fall, I put my backhoe on for the first time in a couple of years. Tried pushing a 2'X2'X1' concrete block away from the tractor with the dipper motion. Instant shower of oil all over everything as the pump split.

Just fixing it now. I will put a pressure relief bypass in with the 2nd new pump. I have some questions for anybody who knows hydraulics:

The first image shows how it is plumbed. The original PTO backhoe pump never worked from day 1. I plumb it into return line on the loader.

Image 2 shows the proposed alteration. I will put a Prince VA RV-4-H or a Princess Auto 8688947 Relief valve on pressure line # 1. Ill put gauges in by using a 'T' fitting at two locations so I can keep an eye on how hard I am pushing things in the future.

Questions:

What pressure should I set to?

Can I 'T' into the sump return line #3? If I do, do I need a one-way valve upstream of the 'T' on line #3? (This is a hard line)

Should I drill and tap a new hole into the sump to run the bypass hose into? Should the oil return below the liquid level in the sump?

Do you see any flaws in my plan? Will this fix, as proposed, avoid the same issue when I go out next weekend to finish moving those heavy concrete blocks?

(I am learning hydraulics slowly by fixing this machine. It seems to my logic that this machine is plumbed wrong to begin with. Shouldn't the pressure line off the pump go to the proportioning valve first so as to always give the steering first chance at oil flow. Also the pressure relief is in there? It has a Koyker loader so I guess it came from factory hard line plumbed without consideration of a loader circuit. They plumbed it this way so they did't have to replace hard lines?)

Thanks for any help,

Tim