fawcekj

New member

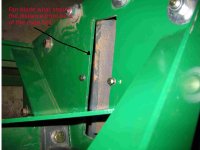

I need some advice on my JM6. I've run about 10cuyds of wood through it in the last couple weeks, mix of dry and green wood, up to about 5" dia. long leaf pine mostly (over 4.5" and my tractor stalls. ) Anyway its been great, and besides I stall trying to lift a 5"x 30' pine tree too. I installed the set screws in the feed roller drive and it has been working well. My current problem is that this weekend after running for a couple hours, it started making a banging noise, and I quickly shut it down. /forums/images/graemlins/confused.gif When I got it back to the barn the chipper blades were hitting the base anvil. So I adjusted the anvil to 0.20 mid way between the spec. 0.10 to 0.3. I also rotated the blades to the good side, about a quarter inch on the outer edge was dinged and the rest of edge was slightly rounded I assume due to impact with the anvil. put the unit back together and engaged the PTO. Slowly increased PTO speed and by the time I got to about 300 rpm it started banging again. It looks like the main shaft for the 24" disk has shifted on its pillow blocks, and the disk has moved forward in the chip cage. There are two set screws on each pillow block bearing, and one was almost falling out, the others were not tight.

Has anyone else had this problem?

Does anyone know what position the disk should be within the chip cage? I was thinking that I would just center it front to back , but then maybe it should be closer to the front to keep the chips cleared to the back of the disk?

Any recommendations to keep it from happening again? LocTight?

Has anyone else had this problem?

Does anyone know what position the disk should be within the chip cage? I was thinking that I would just center it front to back , but then maybe it should be closer to the front to keep the chips cleared to the back of the disk?

Any recommendations to keep it from happening again? LocTight?